Plastic packaging, including plastic bags, plastic bottles, plastic bags, plastic wrap, etc., can be divided into OPP, CPP, PP, PE, PVA, EVA, composite bags, etc. according to the material, and most of them are polymers. Today, the use of a large number of packaging materials is a potential source of environmental matrix pollution. Evaluating the content of harmful elements in packaging materials is directly related to human health.

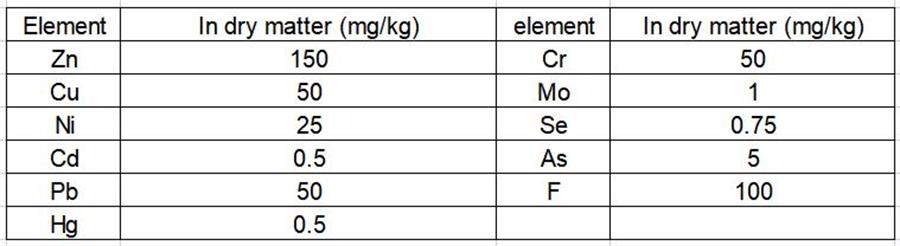

The European Union promulgated the heavy metal detection standard directive for packaging materials to test the 94/62/EC directive , requiring all packaging and materials circulating in the European market to contain lead (Pb), cadmium (Cd), mercury (Hg), hexavalent chromium [Cr (VI)] The total content of the four substances shall not exceed 100 mg/kg. Appendix A (normative appendix) of the directive EN 13432 gives the regulations on the maximum element content allowed for packaging materials and all packaging (see Table 1), and requires the weight of the tested substance to be based on 50% of the residual inorganic minerals (non-degradable of) measurement. The U.S. "CONEG (Reduction) of Toxic Substance Content in Packaging" regulations also limit the sum of Pb, Cd, Hg, and Cr(VI) to no more than 100 mg/kg. With reference to relevant EU laws and regulations, China also stipulates that the total content of four heavy metal elements in packaging and packaging materials should not exceed 100 mg/kg in "Packaging and the Environment Part I: General Rules" GB/T 16716.1-2018 .

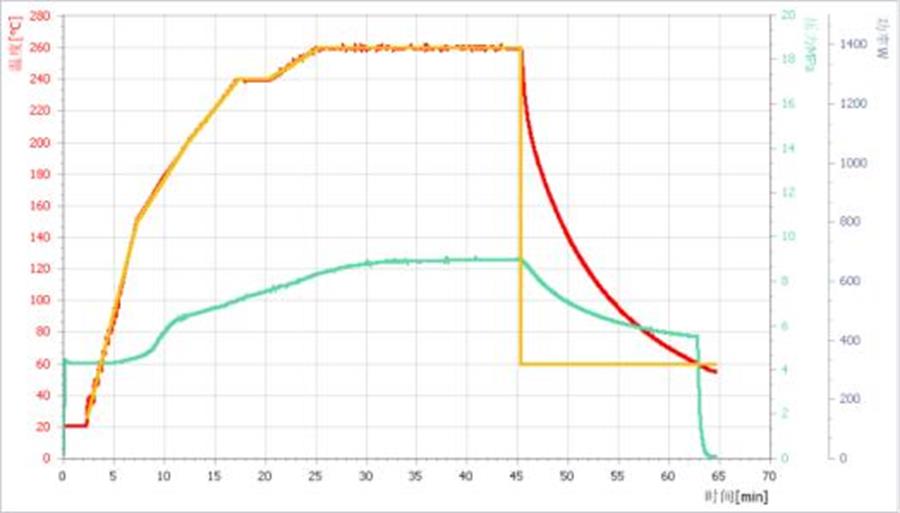

According to "ICP-MS method for detection of arsenic, barium, cadmium, chromium, mercury, lead, selenium and antimony in import and export packaging materials" SN/T 3881-2014, the pretreatment method is microwave digestion, but plastic packaging materials are required to be pre-treated Digestion, because the polymer sample will generate a lot of pressure during the digestion process, and the traditional microwave digestion system may burst the tube. Due to its own characteristics, the super microwave has the same pressure in the entire digestion system , so there will be no tube burst. In this paper, super microwave digestion was carried out for plastic packaging samples, and the nitric acid-hydrochloric acid digestion system was used to achieve complete digestion of plastic packaging.

Experimental part

Instrument

Reagents and Standards

- Reagents: premium pure nitric acid, hydrochloric acid;

- Pure water: 18.2 MΩ·cm deionized water (25°C);

Sample pretreatment

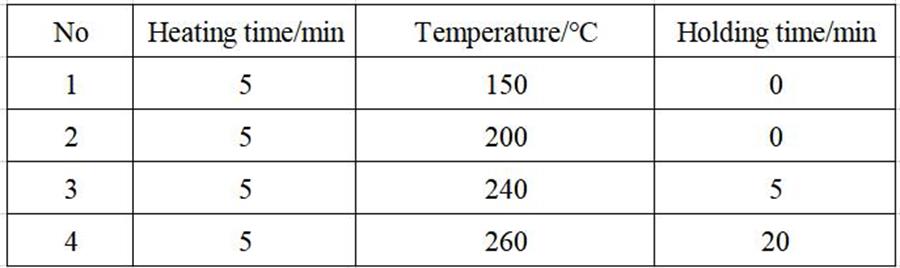

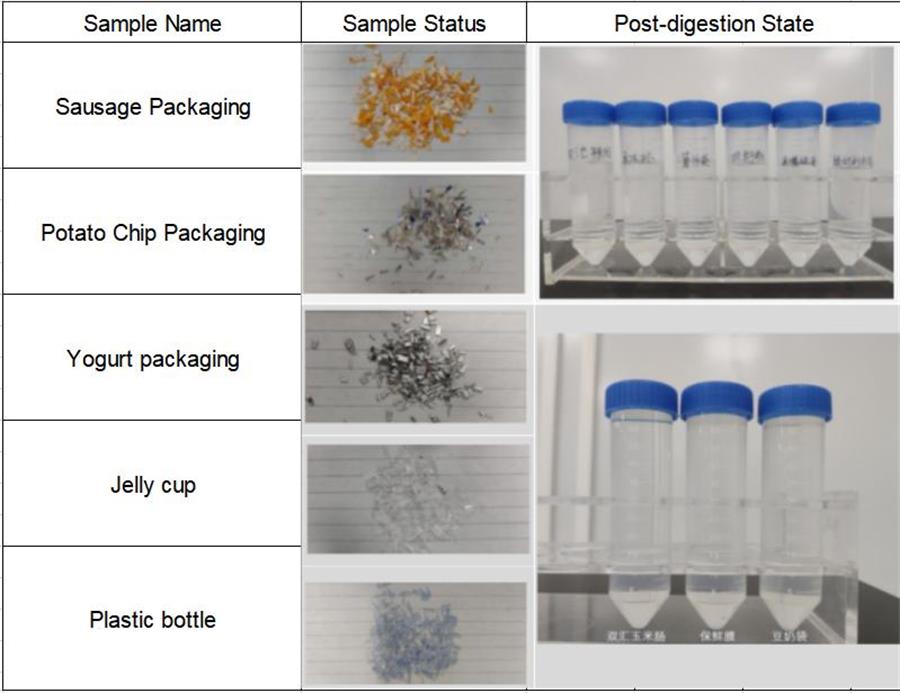

Weigh 0.2 g (accurate to 0.0001 g) of shredded plastic packaging samples into a digestion tube, add 5 mL of nitric acid and 0.5 mL of hydrochloric acid, and transfer to a super microwave platform. Digest according to the program in Table 3, after cooling, dilute to volume with deionized water.

Table 3 Super microwave digestion program

Epilogue

This article uses super microwaves, which can completely digest plastic packaging. No pre-digestion is required, the temperature is stable throughout the digestion process, the pressure does not change drastically, and the digestion solution is clear and transparent.

Appendix

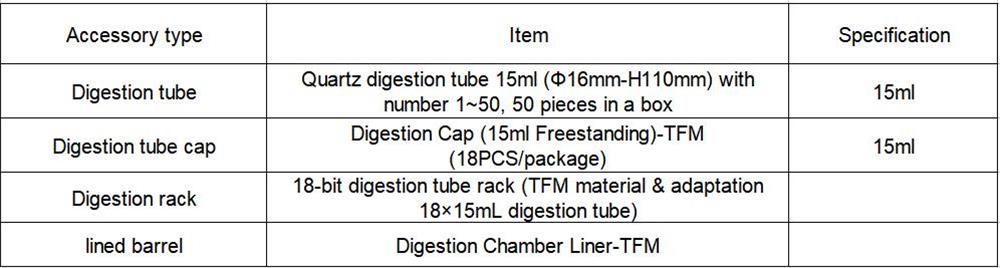

Equipment and Consumables Solutions

Super microwave configuration details