Lubricating oil is an important product that is widely used in many fields such as machinery manufacturing, transportation and shipping, and petroleum industry. The content of additive elements in lubricating oil is usually one of the important indicators indicating the quality and performance of oil products. The content of wear elements and pollution elements in lubricating oil is an important parameter to monitor the performance of lubricating oil and predict the failure of various lubricating machinery.

At present, the inorganic pretreatment methods used for lubricating oil include dry ashing, wet digestion and microwave digestion. However, these preprocessing methods have their own defects. The dry and wet digestion method is cumbersome to operate, which will lead to the loss of volatile elements (mercury), long pretreatment time, and a large amount of acid; the conventional microwave digestion method uses a large amount of acid and takes a long time to cool down. Compared with the above methods, the super microwave digestion method has a digestion time of about half of the conventional microwave digestion time, and the amount of acid used is about two-thirds of the conventional microwave digestion time, the cooling time is shorter, and the operation is more convenient. At the same time, the volatile elements More difficult to lose and other characteristics.

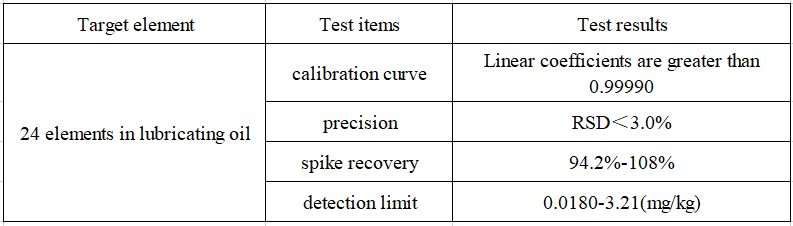

In this experiment, a super microwave digestion-inductively coupled plasma emission spectrometry method was established to determine the content of impurity elements in lubricating oil, and the lubricating oil samples were determined. From the experimental results, the lubricating oil samples can be digested by nitric acid one-time microwave . Use inductively coupled plasma emission spectrometry to measure and analyze 24 kinds of impurity elements in lubricating oil. After the sample is digested to a constant volume, it can be tested directly on the machine. Multiple elements can be measured at the same time, which greatly improves the detection efficiency of the sample. Through method verification and actual sample testing, it can be Fast and accurate determination of impurity elements in lubricating oil.

Key words: super microwave, chemical industry, lubricating oil, impurity elements, ICP-OES

Experimental part

Instrument

Table 1 Inductively coupled plasma optical emission spectrometer and super microwave digestion instrument

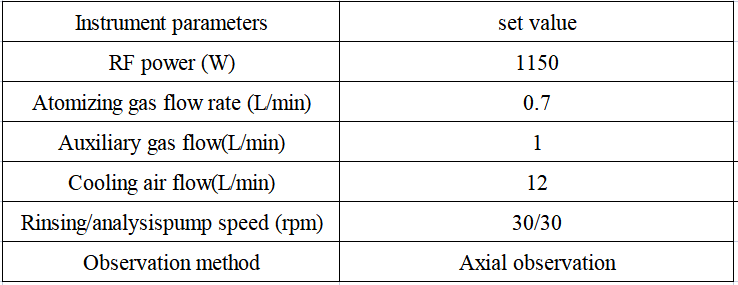

Table 2 Detection parameters of inductively coupled plasma emission spectrometer

Reagents and Standards

Reagent: premium pure nitric acid;

Pure water: 18.2 MΩ·cm deionized water (25°C);

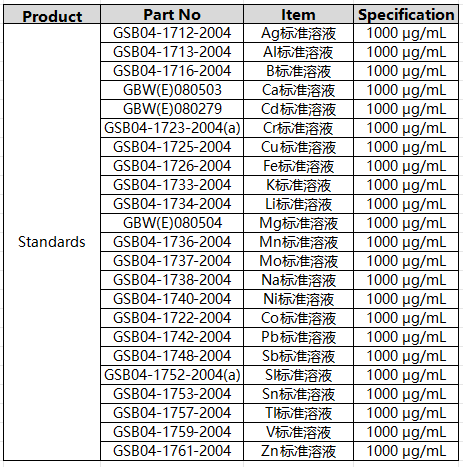

Standard solution: Ag, Cu, Al, Fe, B, K, Ca, Li, Cd, Mg, Cr, Mn, Mo, Na, Ni, P, Pb, Sb, Si, Sn, Ti, V, Zn-single Element standard solution, 1000 μg/mL, National Institute of Nonferrous Metals.

Sample pretreatment

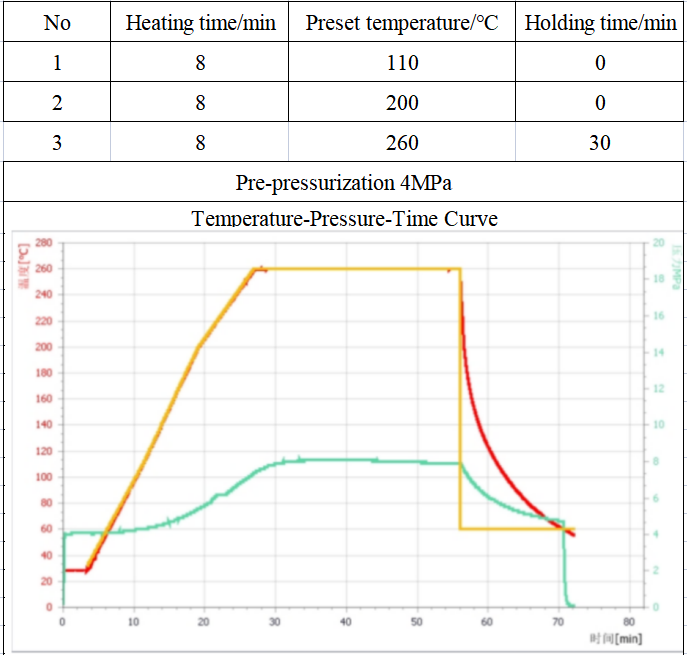

Weigh 0.1 g of sample into a digestion tube, add 1 mL of pure water and 3 mL of nitric acid, shake evenly, and place it in a super microwave chemical workstation for pretreatment according to the following heating procedure. After the digestion is completed, place the digestion tube on the acid flusher, set at 130°C, and carry out acid flushing until the sample volume is about 1 mL, and then cool to room temperature. Rinse the digestion tube at least three times with ultrapure water, transfer it together and dilute to 20 mL. Some elements need to be diluted to an appropriate multiple for testing on the machine. Sample blanks and parallel samples were prepared in the same way.

Table 3 Super Microwave Heating Program

Table 4 Pictures of samples after digestion

Test Results

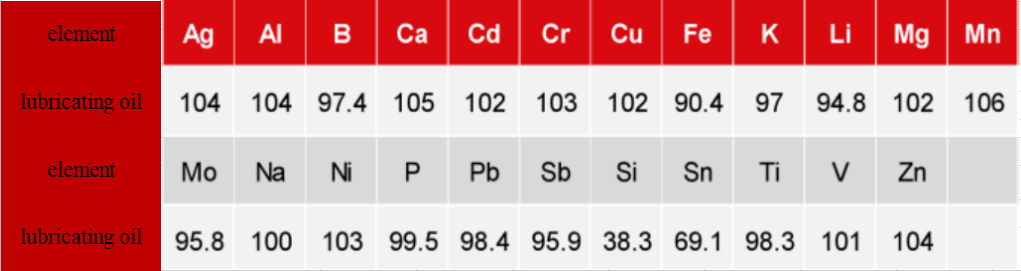

Actual sample test

Using the above method to test the actual samples of lubricating oil, the results are shown in Table 5. The analysis data of the lubricating oil samples show that the content of most impurity elements in the lubricating oil is basically the same, indicating that the impurity elements in the lubricating oil are added.

Table 5 Test results of lubricating oil samples (unit: mg/kg)

Epilogue

This experiment established a super microwave digestion-inductively coupled plasma emission spectrometry method for the determination of Ag, Al, B, Ca, Cd, Cr, Cu, Fe, K, Li, Mg, Mn, Mo, Na, Ni in lubricating oil , P, Pb, Sb, Si, Sn, Ti, V, Zn and other 24 element content analysis methods. From the experimental results, the lubricating oil can be digested by one microwave. The linear coefficients of the standard curves established in this paper are all greater than 0.9990. The precision test results of each element in the actual sample are RSD<3.0%. (mg/kg), indicating that the method has good stability and precision, and can accurately determine the content of impurity elements in lubricating oil.

Appendix

Equipment and Consumables Solutions

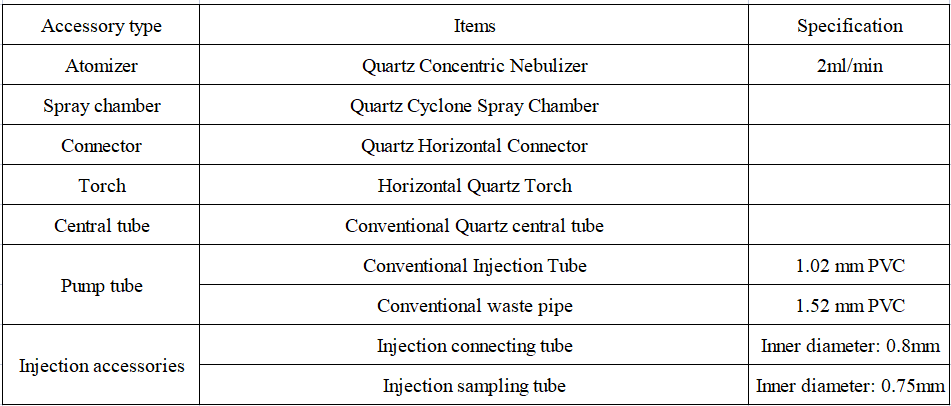

1. Configuration details of EXPEC 6100 standard sampling system

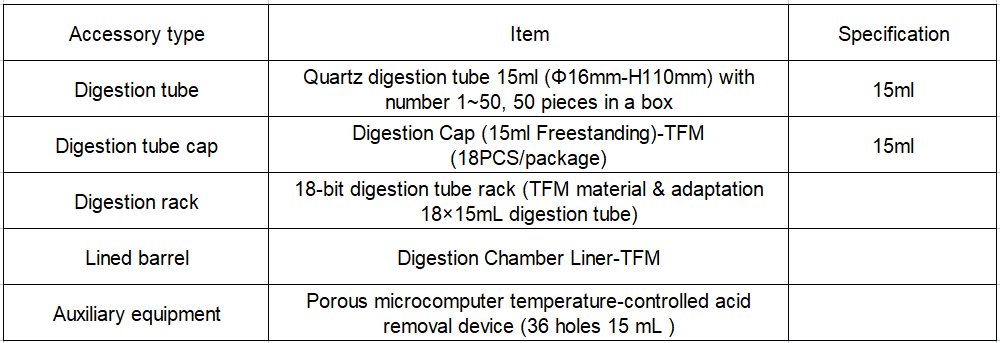

2. Configuration details of EXPEC 790S Super Microwave Chemical Workstation

3. Reagents and Standards