Graphene powder is currently the main form of graphene products in my country, and has initially achieved large-scale applications in the fields of new energy batteries, thermal management, and heavy-duty anti-corrosion coatings. Graphene powder can be prepared through different production processes such as mechanical exfoliation, reduction oxidation, intercalation dissociation, and small molecule synthesis. Due to differences in production processes, production equipment, raw materials, etc., the types and contents of metal impurity elements contained in graphene powders produced by different manufacturers are also significantly different. Metal impurities will directly affect the application performance of graphene powder . The development of graphene application technology and industrial development need to establish a standardized analytical test method for accurate and reliable detection of metal impurities in graphene powder.

"Determination of Metal Impurities in Nanotechnology Graphene Powder by Inductively Coupled Plasma Mass Spectrometry" GB/T 42240-2022 specifies the microwave digestion method and inductively coupled plasma mass spectrometry of graphene powder samples to quantitatively test impurity elements, but The sample weight of this method is only 10 mg, which is difficult to be representative when the sample is not uniform enough. In this paper, super microwave was used to digest graphene powder, the sample weight was 100 mg, and the nitric acid-perchloric acid system was used for digestion, and the sample could be completely digested. The inductively coupled plasma atomic emission spectrometry is used to test, and the standard addition recovery rate of the results is shown, and the precision is good, and it can be used as a quantitative test and analysis method for metal impurities in the graphene powder.

Experimental part

Instrument

Table 1 Instrument selection and configuration

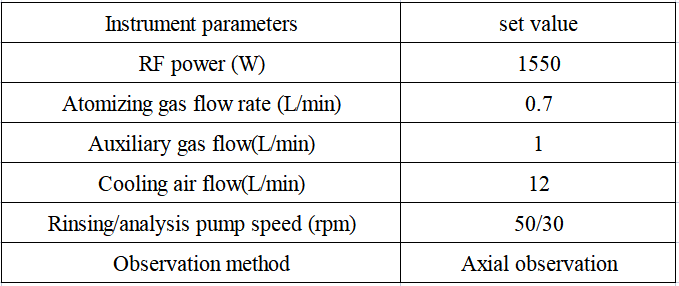

Table 2 Detection parameters of inductively coupled plasma emission spectrometer

Reagents and Standards

Reagents: nitric acid, perchloric acid, all of superior grade

Pure water: 18.2 MΩ·cm deionized water;

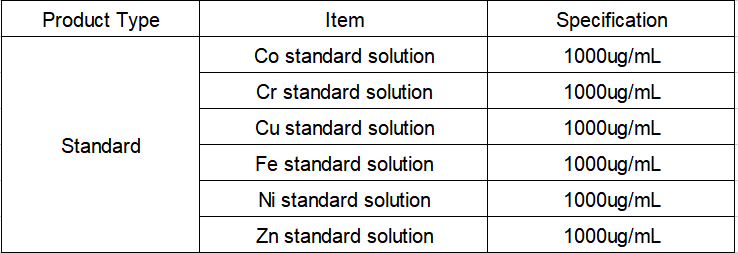

Standard solution: cobalt, chromium, copper, iron, nickel, zinc single element standard solution, 1000 μg/mL, National Institute of Nonferrous Metals.

Sample pretreatment

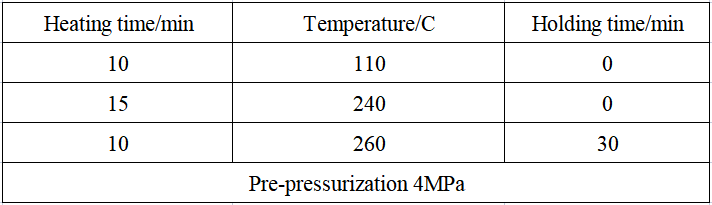

Accurately weigh 0.1 g of the sample (accurate to 0.0001 g), place it in a digestion tube, add 1 mL of nitric acid and 3 mL of perchloric acid, cover the lid and place it on the digestion tube rack, and use 150 mL+5 mL of nitric acid as the carrier liquid. Transfer to super microwave according to the procedure in Table 3 for microwave digestion. After the digestion is complete, take it out after cooling, and dilute to 50 mL with deionized water. The super microwave digestion procedure is as follows:

Table 3 Super Microwave Heating Program

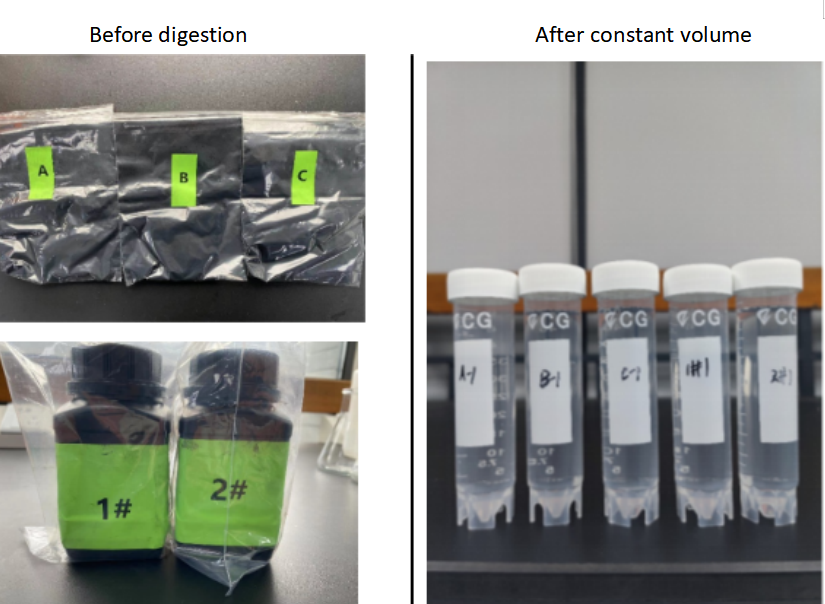

Table 4 Pictures of samples after digestion

Test Results

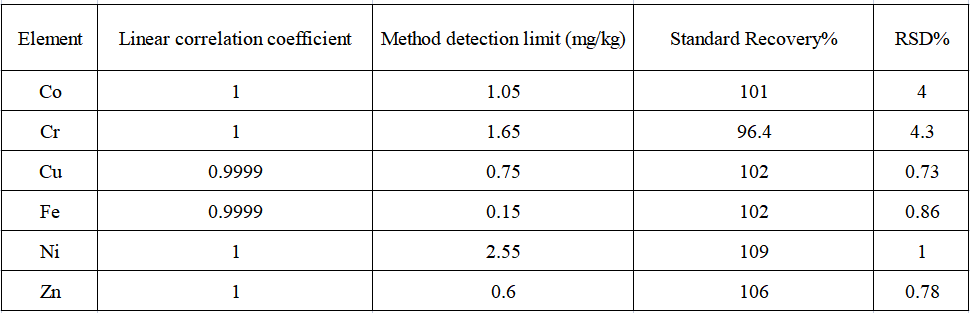

Linearity and detection limit: the linear correlation coefficient values of all analytes are greater than 0.9999. The sample concentration corresponding to 3 times the standard deviation of the measured value obtained by continuous analysis of the blank sample for 11 times was used as the detection limit of the method.

Precision test: 7 parallel samples of sample A were tested separately, and the result precision RSD%<4.3%, and the RSD% was calculated by adding standard for undetected elements.

Spike recovery rate test: The spike recovery rate test was performed on the samples, and the appropriate concentration was selected according to the element content for spike, and the spike recovery rate of each element was between 96.4 and 109%.

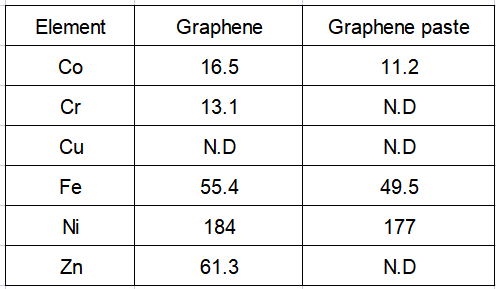

Actual sample test

Using the above method to test the actual samples, the results are shown in Table 2.

Table 2 Sample test results (unit: mg/kg)

Epilogue

Inductively coupled plasma atomic emission spectrometry was used to test the results, which showed the recovery rate of the standard addition, good precision, and accurate and reliable test results; two or more identical samples were taken for independent experiments, with completely consistent conditions (digestion methods, reagents) , instruments and analysts) for analysis, to examine the consistency of the results, and the parallelism of the samples is good. It can be used as a quantitative test and analysis method for metal impurities in graphene powder.

Appendix

Equipment and Consumables Solutions

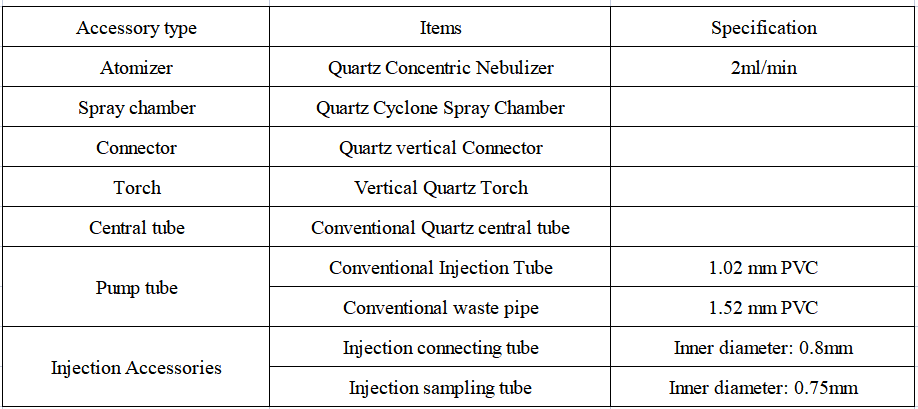

1. Configuration details of EXPEC 6100D ICP-OES standard sampling system

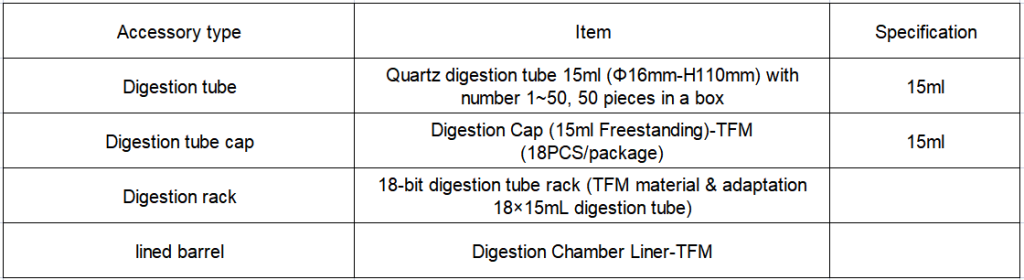

2. Configuration details of EXPEC 790S Super Microwave Chemical Workstation

3. Reagents and Standards