The Instrument: The EXPEC 4820 is a mid-range CCD/CMOS spectrometer available as a dedicated single- base unit as well as a versatile multi-base system. The EXPEC 4820 model is an instrument used widely across different segments of the metals industry. It is well suited for the metal production and inspection and perfectly suited for the metal processing industry. The EXPEC 4820 analyses main alloy elements, as well as trace elements.

Method: Aluminium – magnesium alloys were prepared using conventional lathe. This is a recommended sample preparation method for all industrial soft materials. Nickel, Stainless Steel, and Brass Alloys were prepared using conventional linisher. This is a recommended sample preparation for all industrial hard materials. The instrument was purged with argon for 30 minutes before testing any samples. Average of three burns were performed on each sample. All the results obtained were recorded by EXPEC software.

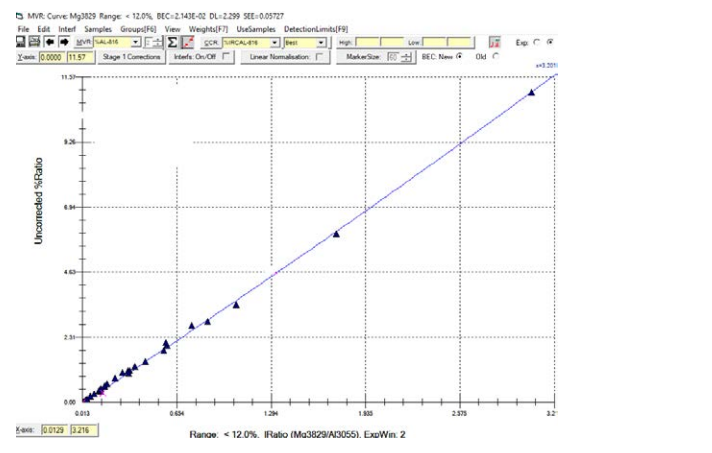

Graph1: Example of the curve obtained for Magnesium in Aluminium- Magnesium

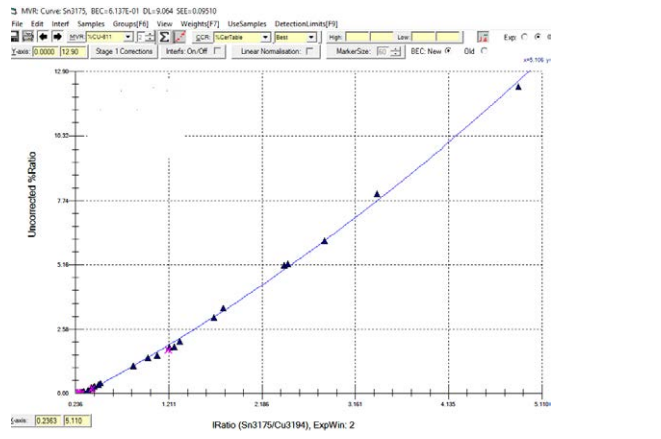

Graph2: Example of the curve obtained for Tin in Brass program.

Conclusion: The results were obtained within range of 0.005 – 24% for Silicon and 0.01 – 7% for Copper in Aluminium-Silicon-Copper program. Results referenced to AA3xx.x, EN AC 45000, 46000, 47000, EN AW4000, EN AC 41000-44000 and the AA 4xx.x.

The results were obtained within range of 0.001 – 10% for Tin and 0.5 – 45% for Zinc in Brass program.

The results were obtained within range of 6-32% for Chrome and 3-50% for Nickel in Chrome- Nickel program (Stainless Steel).

The results were obtained within range of 2-30% for Chrome, 0.005-15% for Cobalt and 0.005- 16% for Molybdenum in Inconel program.

EXPEC 4820 is the right model for this application.