The Instrument: The EXPEC 4850 is an instrument used widely across different segments of the metals industry.

Customers often demand tight QC at every step of the supply chain. Every part must meet strict specifications throughout the manufacturing process. The EXPEC 4850 analyses all main alloy elements, as well as trace elements.

Method: Aluminium – Silicon – Copper Alloys were prepared using conventional lathe. This is a recommended sample preparation method for all industrial soft materials. Steel samples has been prepared using a linisher. This is a recommended sample preparation method for all industrial hard materials. The instrument was purged with argon for 30 minutes before testing any samples. Average of three burns were performed on each sample. All the results obtained were recorded by EXPEC software.

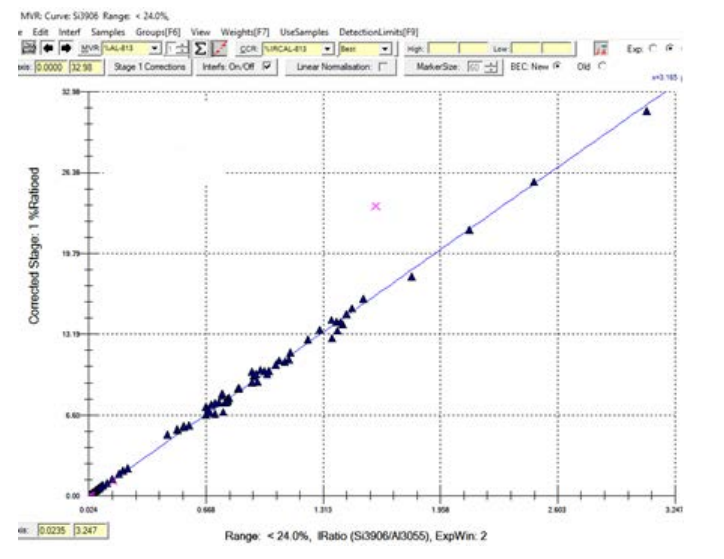

Graph1: Example of the curve obtained for Silicon in Silicon-Copper program.

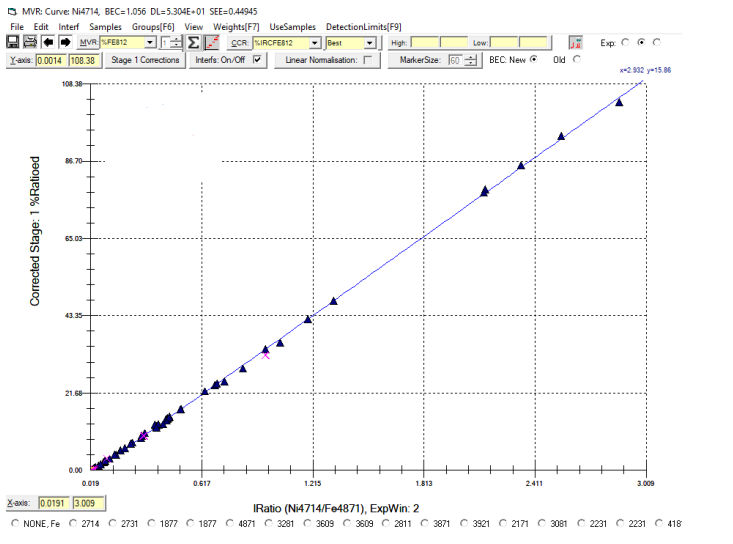

Graph2: Example of the curve obtained for Nickel in Chrome- Nickel program.

Conclusion: The results were obtained within range of 0.002 – 24% for Silicon and 0.0008 – 7% for Copper in Silicon-Copper program. Results referenced to AA3xx.x, EN AC 45000, 46000, 47000, EN AW4000, EN AC 41000- 44000 and the AA 4xx.x.

The results were obtained within range of 3-50% for Nickel and 6-32% for Chrome in Chrome- Nickel Steel program. Results referenced to 300 and 400 series.

EXPEC 4850 is the right model for this application.