Silicon carbide has excellent thermal conductivity , stable chemical properties, small thermal expansion coefficient, good wear resistance, and high hardness. Silicon carbide mainly has four major application areas, namely: functional ceramics, advanced refractories, abrasives and metallurgical raw materials. It can be used to manufacture semiconductors, silicon carbide fibers, etc., and is an engineering processing material for the solar photovoltaic industry, semiconductor industry, and piezoelectric crystal industry. Silicon carbide and gallium nitride are also known as third-generation semiconductor materials, which have the advantages of high breakdown electric field, high thermal conductivity, high electron saturation rate, and strong radiation resistance. Therefore, semiconductors prepared by using third-generation semiconductor materials The device can not only operate stably at a higher temperature and is suitable for high-voltage, high-frequency scenarios, but also achieve higher operating capabilities with less power consumption.

Impurity elements in high-purity silicon carbide will affect the electrical properties of silicon carbide and directly affect the final product quality. Therefore, the analysis of elemental impurities in high-purity silicon carbide is of great significance in industrial production. The traditional method generally uses pressurized acid dissolution for pretreatment of high-purity silicon carbide: use a high-pressure closed digestion tank, 5 mL hydrofluoric acid + 8 mL nitric acid + 5 mL sulfuric acid, and place in an oven at 240 °C for 16 h. This method takes a long time to process, and the high-pressure closed digestion tank also has a certain risk of bursting the tank. Based on the characteristics of high temperature and high pressure of super microwave digestion instrument , this application center has developed a high-purity silicon carbide digestion method, the digestion time is shortened to less than 2 hours , and the digestion solution is clear and transparent, which meets the needs of back-end instrument testing.

Key words: super microwave, silicon carbide, material

Experimental part

Instrument

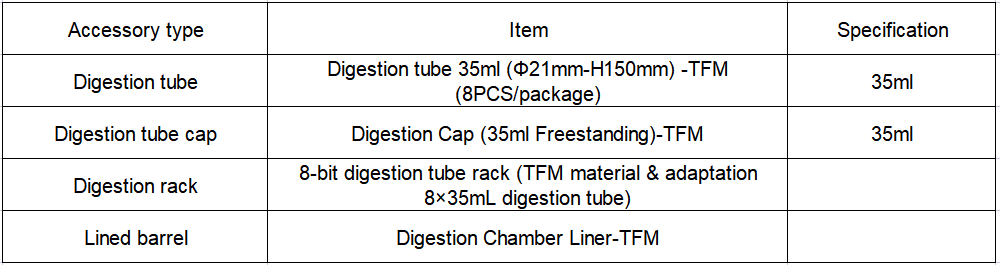

Table 1 Super Microwave Digester

Reagents and Standards

Reagents: superior pure nitric acid, sulfuric acid, hydrofluoric acid;

Pure water: 18.2 MΩ·cm deionized water (25°C);

Sample pretreatment

Weigh 0.05 g (accurate to 0.0001 g) of silicon carbide sample into a digestion tube, add 3 mL of nitric acid, 3 mL of hydrofluoric acid, and 6 mL of sulfuric acid, and transfer to a super microwave platform. Digest according to the program in Table 2, after cooling, dilute to volume with deionized water.

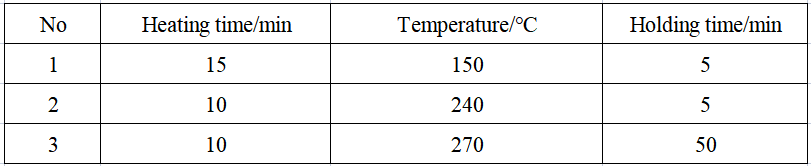

Table 2 Super microwave digestion program

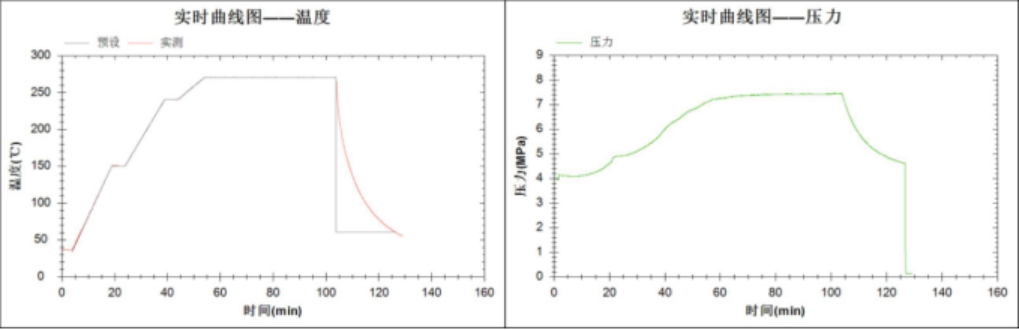

Figure 1 Super Microwave Heating Curve

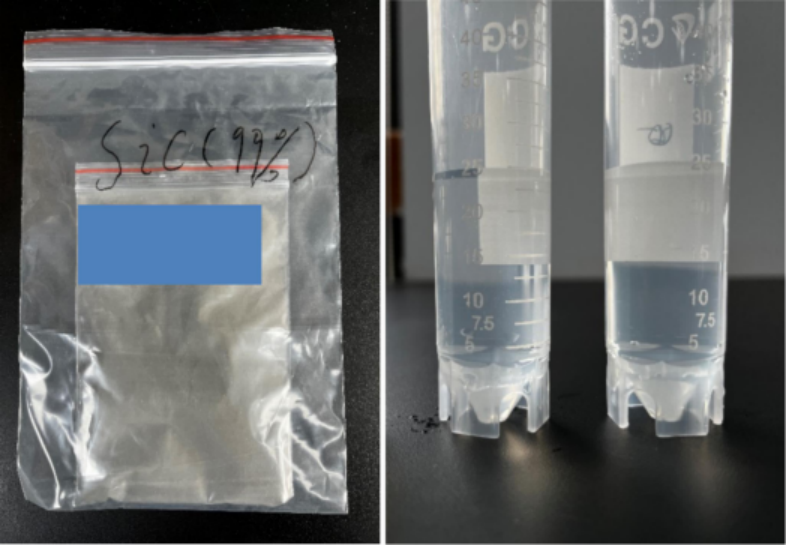

Figure 2 Pictures before and after sample digestion

Epilogue

This program uses super microwave, which can completely digest silicon carbide. The entire digestion time is about 2 hours, the digestion temperature is stable, the pressure does not change drastically, and the digestion solution is clear and transparent, which can be used as a pretreatment method for silicon carbide.

Appendix

Equipment and Consumables Solutions

1. Super microwave configuration details