Aluminum alloy has low density, but relatively high strength and good plasticity. Silicon-aluminum alloy materials can maintain the excellent properties of silicon and aluminum. Increasing the silicon content can significantly reduce the density and thermal expansion coefficient of alloy materials. Silicon-aluminum alloy also has excellent plating properties with gold, silver, copper, and nickel, can be welded to the base material, and is easy to be precision machined. It is an electronic packaging material with broad application prospects, especially in aerospace and space. high-tech fields such as technology and portable electronic devices. When the product is used in key core components, if there is a false standard for the element content in the aluminum alloy, it can easily cause various quality problems. Especially when used in aerospace, it will cause greater quality accidents, and these problems only It is impossible to make a correct judgment from the appearance, so attention must be paid to the detection of the content of various alloy elements in aluminum alloys.

Due to the high silicon content of silicon-aluminum alloy materials, special attention must be paid to sample dissolution and measurement methods when conducting chemical analysis of such materials. There are many types of measurement methods in current standards. Among them, Part 5 and Part 25 of "Methods for Chemical Analysis of Aluminum and Aluminum Alloys" (GB/T 20975.5-2020) use spectrophotometry, gravimetric method and inductively coupled plasma optical emission spectrometry (ICP-OES) respectively to analyze the Si element. Make a determination. As a high-precision, high-sensitivity, and high-throughput elemental analysis technology, ICP-OES technology has become one of the mainstream methods for determining element content in alloy samples. Compared with traditional elemental analysis technology, ICP-OES technology has higher analysis speed and accuracy, and can measure multiple elements simultaneously. Therefore, when analyzing the silicon element in high-silicon aluminum, the content of other elements can be analyzed and measured at the same time, thus greatly improving the analysis efficiency.

This article refers to the alkali dissolution method in the chemical analysis method of aluminum and aluminum alloys and combines the EXPEC 6500D ICP-OES to test the contents of copper, zinc, lead, cadmium, beryllium, barium, nickel and chromium in high-silicon aluminum alloys. The test data has good parallelism and accuracy and can be used as a test and analysis method for high-silicon aluminum alloys.

Keywords: alloy; aluminum alloy; ICP-OES; alkali dissolution; silicon

Experimental part

instrument

Table 1 Inductively coupled plasma optical emission spectrometer

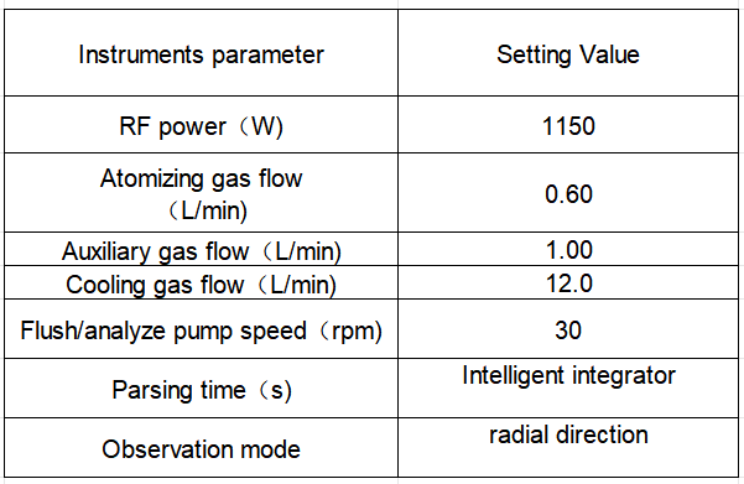

Table 2 Inductively coupled plasma emission spectrometer detection parameters

Reagents and standards

Reagents: high-grade pure nitric acid, high-grade pure hydrochloric acid, sodium hydroxide (>99.9%);

Pure water: 18.2 MΩ·cm deionized water;

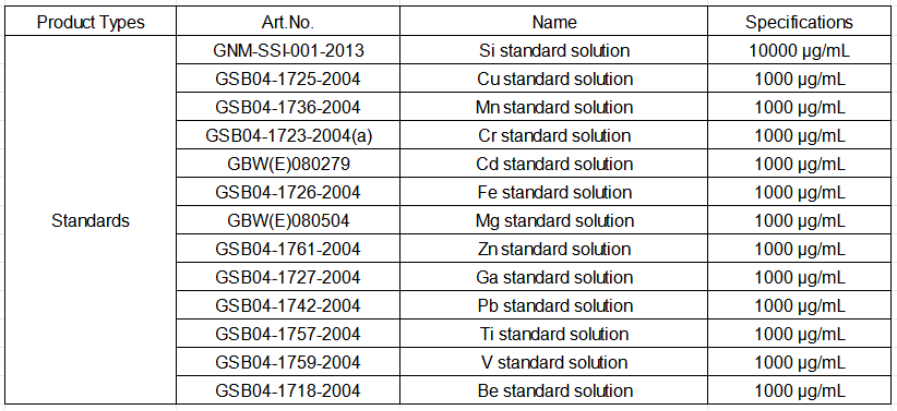

Standard solution: Si, Cu, Mn, Cr, Cd, Fe, Mg, Zn, Ga, Pb, Ti, V, Be, P, Ni, W, Mo, Nb, Co, Ai single element standard solution, 1000 μg/mL, National Research Institute of Nonferrous Metals.

Sample preparation

Accurately weigh 0.1 g of the sample and place it in a polytetrafluoroethylene beaker. Add 20 ml of 10% NaOH and heat it on a hot plate for digestion. After the sample is digested, add 10 ml of 1:1 HCl and 10 ml of 1:1 HNO3 in sequence. Shake well and make up to 100 ml for testing.

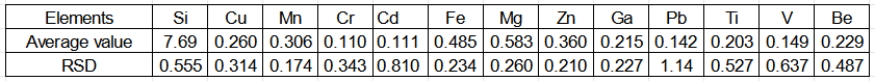

Precision test

Seven parallel samples of ZBY5061 were tested separately, and the results showed that the precision RSD% was <1.5%, which is good and can be used for actual sample analysis.

Table 5 Sample precision data (%)

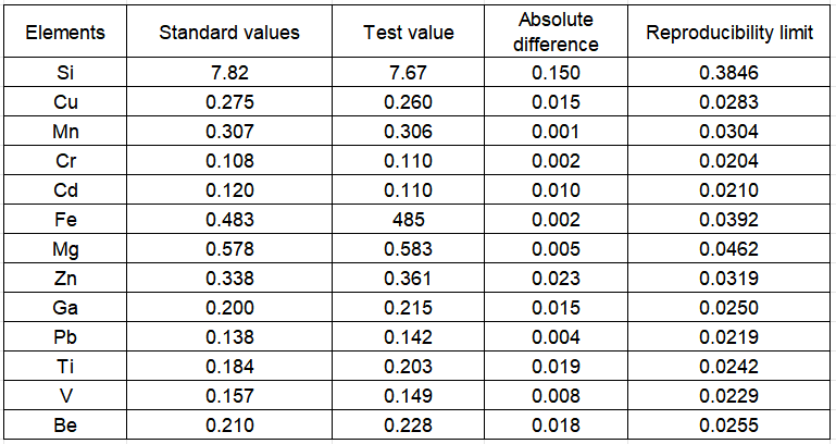

Accuracy test

The ZBY5061 silicon aluminum sample was tested using the above method. The measured value was compared with the standard value. The absolute difference value met the reproducibility requirements of the standard GB/T 20975.25-2020, indicating that the test results were accurate and reliable.

Table 6 ZBY5061 sample test results and absolute deviation (unit: %)

in conclusion

The above experimental results show that using the standard configuration EXPEC 6500D inductively coupled plasma optical emission spectrometer to measure the element content in silicon-aluminum alloy samples is of great significance for studying the properties of aluminum alloy materials. The measurement results show that the method detection limit of the element to be measured is 0.00001%~0.00082%, the precision is <1.5%, and the precision is good. The absolute error of the measurement meets the reproducibility limit required by the national standard GB/T 20975.25-2020. This method is fast and has high data reliability, and can be widely used in the detection of silicon-aluminum alloy content.

appendix

Equipment and consumables solutions

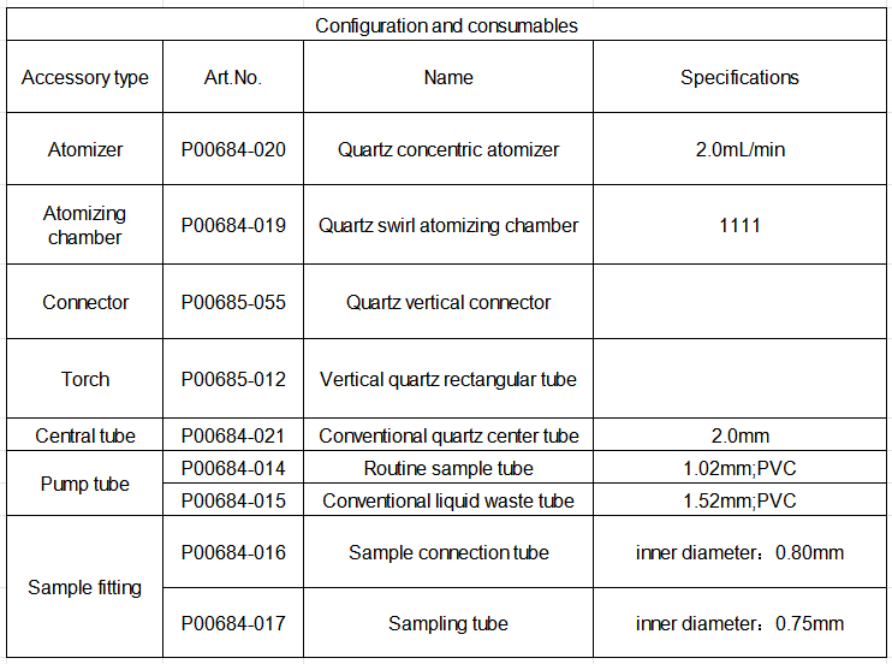

1. Configuration details of EXPEC 6500D standard sampling system

2. Reagents and Standards