Since the mid-to-late 20th century, iodine deficiency diseases have been prevalent in various degrees in various regions of my country. After the promulgation of the "Comprehensive Prevention and Control of Iodine Deficiency Regulations" in 1994, the measures of adding iodine to table salt have gradually eliminated the hazards of iodine deficiency in my country. However, with the improvement of people's living standards, the intake of seafood with high iodine content has increased significantly, and some areas have experienced the hazards of iodine excess. In 2009, the World Health Organization issued a warning that China is already a risk area for hyperthyroidism caused by iodine. The iodine in the human body mainly comes from food, and the accurate determination of iodine in food is of great significance for food safety and human health.

Inductively coupled plasma mass spectrometer (ICP-MS) has gradually become the instrument of choice for elemental analysis in food laboratories due to its high sensitivity, wide dynamic linear range, multi-element simultaneous analysis and good stability. The new national standard GB 5009.267-2020 issued in September 2020 stipulates that the first method for the determination of iodine in food is inductively coupled plasma mass spectrometry (ICP-MS method). The gas chromatography method stipulated in the old national standard GB 5009.267-2016 involves more reagents, more complicated sample processing, longer time-consuming, higher method detection limit and lower precision. In contrast, the sample pretreatment steps of the ICP-MS method stipulated in the new national standard are very simple. It only needs liquid phase extraction and constant volume filtration, and then it can be analyzed on the machine, and this method has lower detection limits and higher of precision. Therefore, the ICP-MS method in the new national standard undoubtedly has greater advantages.

EXPEC Technology SUPEC-7000 ICP-MS has excellent sensitivity, strong matrix tolerance, reliable stability, and efficient collision reaction cell technology to reduce interference, and can obtain excellent accuracy in the test of iodine in milk powder , precision and repeatability. In view of the above, this article takes EXPEC Technology SUPEC-7000 ICP-MS as an example to provide a new solution for the determination of iodine in milk powder.

Experimental part

Instrument

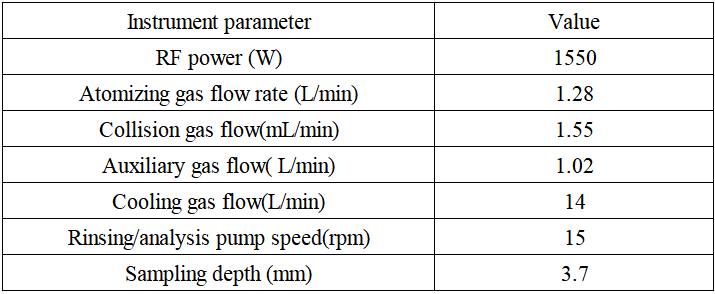

Table 1 Inductively coupled plasma mass spectrometer

Table 2 Detection parameters of ICP-MS

Reagents and Standard Solutions

- Ultrapure water (resistivity ≥ 18.2 MΩ cm, 25°C);

- Tetramethylammonium hydroxide (TMAH, 25% mass fraction);

- Iodine standard solution (1000 ug/mL, Beijing Nonferrous Metals);

- Tellurium standard solution (1000 ug/mL, Beijing Nonferrous Metals).

Sample pretreatment

The monitoring mode is multi-reaction monitoring (MRM), and the N-nitrosodimethylamine compound monitors the ion pair, cone voltage, collision energy and other parameters as shown in the figure below.

- (1) Prepare 5% TMAH solution as the extractant, accurately weigh 0.2 g (accurate to 0.001 g) of milk powder into 5 mL of extractant, vortex and mix well, and place in a constant temperature drying oven at 80 °C for 3 h;

- (2) Cool to room temperature after taking it out, and dilute to 50 mL with ultrapure water;

- (3) Centrifuge at 5000 r/min for 10 min and then filter with a 0.45 μm membrane to obtain a clear solution that can be directly injected for testing.

Results and discussion

Measurement results

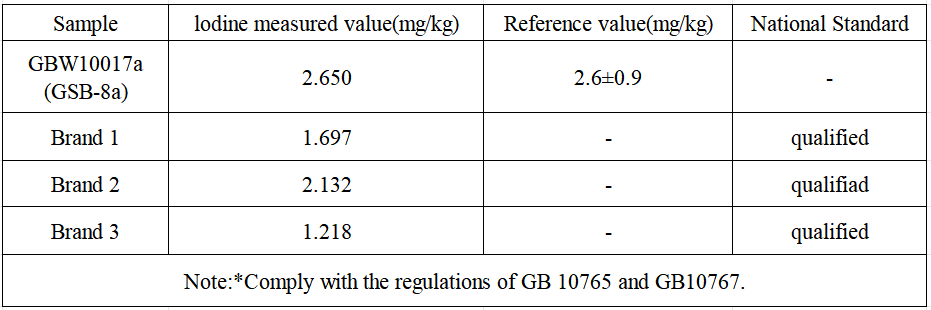

GBW10017a (GSB-8a) milk powder standard was used as a reference to verify the accuracy of the method, and the measured value was in good agreement with the reference value, proving that the analytical results had high accuracy. In addition, three different brands of commercial milk powder were selected for analysis, and the results showed that the iodine content of the three brands of milk powder all met the requirements of the national standards GB 10765 and GB 10767.

Determination results of standard milk powder and commercial milk powder

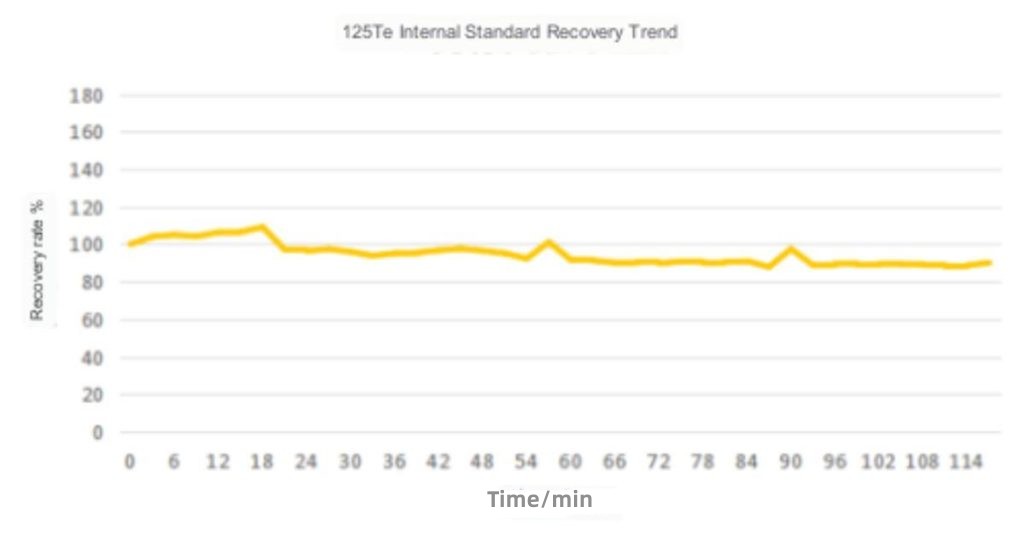

Internal standard stability

- In the long-term test with a total duration of about 2 hours, the recovery rate of the internal standard remained between 87% and 109% for the milk powder samples of different matrices, which proved that the instrument has good internal standard stability.

Internal Standard Stability Trend

Conclusion

- It is difficult to determine the iodine content in milk powder by inductively coupled plasma mass spectrometry. First of all, iodine element is easy to remain in the sampling system and has a strong memory effect. In this method, we can use 0.25% TMAH solution to clean the sampling system, and monitor the response value of iodine element in the software manual tuning mode to judge whether it is cleaned. After testing, after injecting an iodine sample with a concentration of 20 ppb, it only takes about 2 minutes to clean the residual iodine in the sampling system, which is very convenient. Secondly, unlike the acidic sampling system used in the common ICP-MS detection, the new national standard adopts an alkaline sampling system of 0.5% TMAH, and the milk powder sample extract has a higher matrix content, which has a great impact on ICP - The alkali resistance and high matrix tolerance of MS put forward higher requirements. In response to this situation, the conventional means is to turn on the online argon dilution system to reduce the matrix concentration. However, in this experiment, without turning on the online argon dilution system, SUPEC 7000 still exhibited very good alkali resistance and matrix tolerance, and the internal standard stability and instrument precision were greatly improved during long-term analysis. Well maintained. In addition, from the above test results, SUPEC 7000 ICP-MS has shown good accuracy, precision and stability in the process of analyzing milk powder samples, and the test method is simple, easy, true and reliable. We have reasons to believe that SUPEC 7000 is fully capable of meeting the testing requirements for iodine in food stipulated in the new national standard GB 5009.267-2020.