The separator separates the positive and negative terminals of the battery, preventing short circuits while allowing electrolyte ions to pass through. In the structure of lithium batteries, the separator is one of the key inner components. For the lithium battery series, since the electrolyte is an organic solvent system, a diaphragm material resistant to organic solvents is required, and a high-strength thin-film polyolefin porous film is generally used. The performance of the separator directly affects the capacity, cycle and safety performance of the battery. The content of trace elements in the separator is crucial to the performance of the separator, and people pay more and more attention to the detection of trace elements in the separator. Inductively Coupled Plasma-Atomic Emission Spectrometry (ICP-OES) can simultaneously measure multiple elements in the diaphragm, and has the advantages of high sensitivity, low detection limit, good stability, elimination of background interference, and simultaneous determination of multiple elements. It is widely used For the detection of chemical elements of various raw materials, it has a good performance in the determination of lithium battery diaphragm materials.

The application center uses microwave digestion and ICP-OES to test the contents of aluminum, calcium, cadmium, cobalt, chromium, copper, iron, mercury, potassium, magnesium, manganese, sodium, nickel, lead and zinc in the diaphragm material. The pretreatment is simple and easy to operate, and the test of actual samples has good parallelism and accuracy, which can be used as a multi-element rapid analysis method for diaphragm samples.

Key words: lithium battery, diaphragm, super microwave, ICP-OES

Experimental part

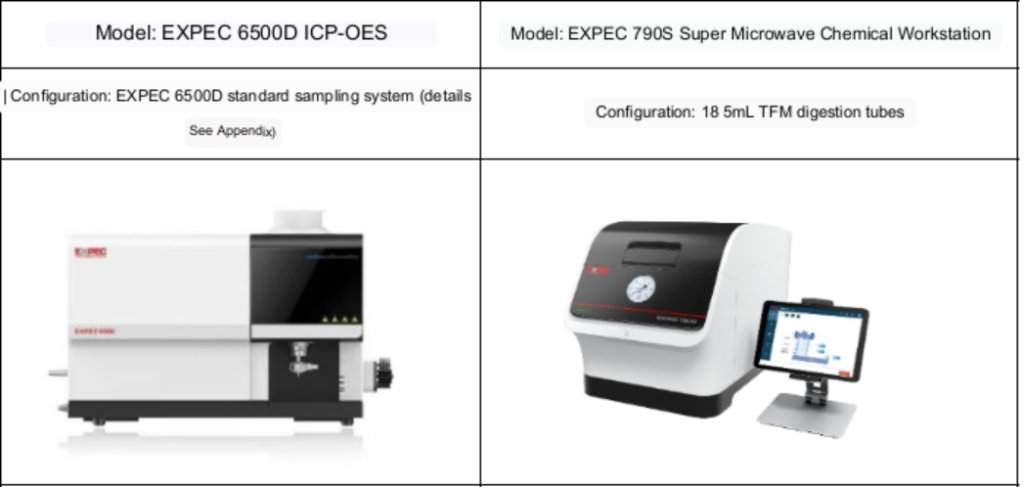

Instrument

Table 1 Inductively coupled plasma emission spectrometer and super microwave

Sample pretreatment

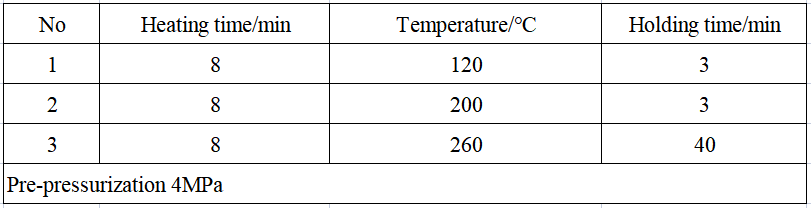

Weigh 0.1 g of sample into the 8-position TFM digestion tube. Add nitric acid, perchloric acid, and phosphoric acid to the digestion tube, sonicate for 5 minutes, and preheat at 120°C for 30 minutes, then put the digestion tube into the digestion tube rack, transfer to the super microwave platform, and perform digestion according to the procedures in Table 3. Take it out after the digestion procedure is completed, and dilute to 25mL with ultrapure water.

The super microwave digestion procedure is as follows:

Table 3 Super microwave heating program

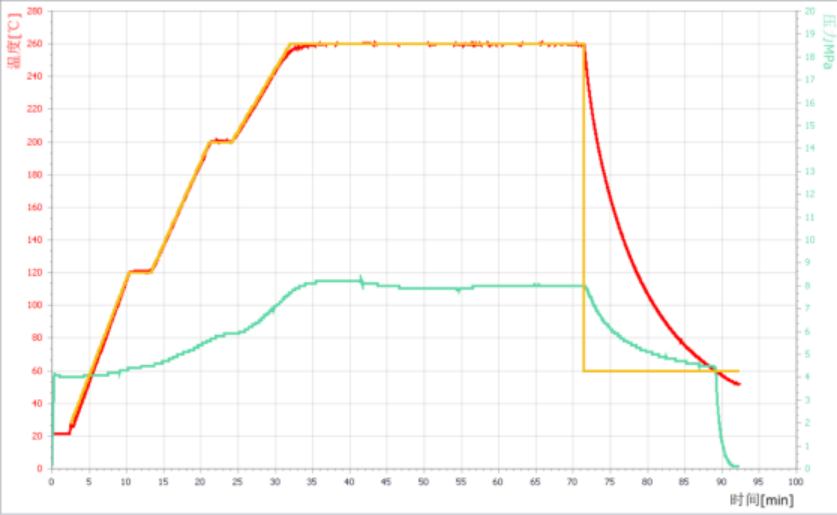

Note: The yellow solid line represents the set temperature, the red curve represents the actual temperature, and the green solid line represents the actual pressure.

Figure 1 Super microwave heating curve

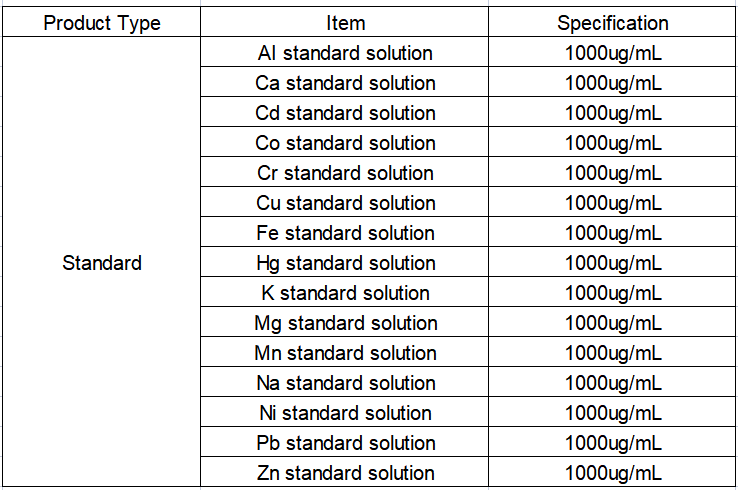

Reagents and Standards

Reagents: superior pure nitric acid, superior pure perchloric acid, superior pure phosphoric acid;

Pure water: 18.2 MΩ·cm deionized water;

Standard solution: Al, Ca, Cd, Co, Cr, Cu, Fe, Hg, K, Mg, Mn, Na, Ni, Pb, Zn 1000 mg/L (National Nonferrous Metals and Electronic Materials Analysis and Testing Center) .

Standard curve and detection limit

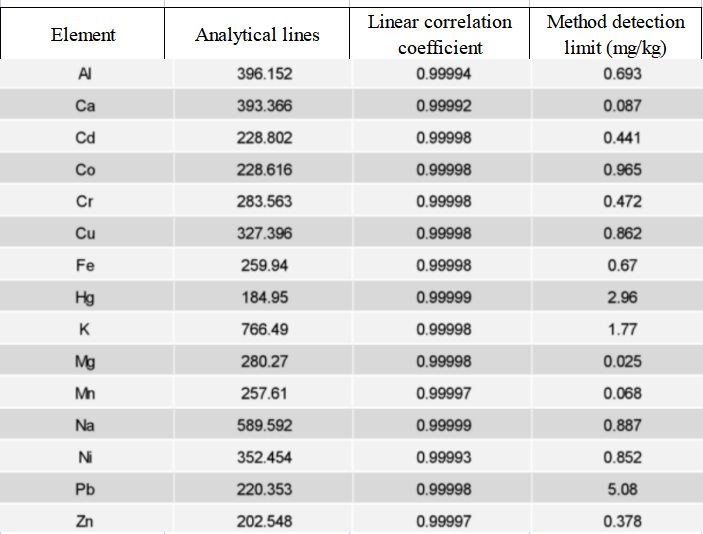

For the analysis samples, select the appropriate sub-analysis line for determination. The linear correlation coefficients of the elements to be measured are all greater than 0.9999, and the linearity is good. And according to the standard definition of the detection limit of the ICP-OES method, the three times standard deviation of the measured value obtained by the continuous analysis of the blank sample for 11 times was used as the detection limit of the method. The results of the correlation coefficient and the detection limit of the method are shown in Table 4.

Table 4 Determination of elemental analysis lines, correlation coefficients and detection limits

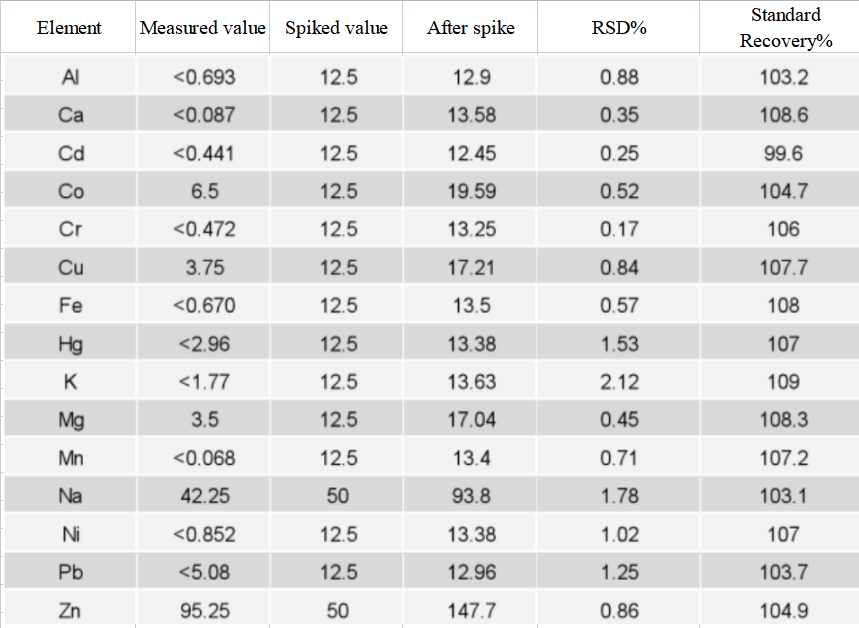

Standard recovery and precision determination

The samples were tested on the machine, and the recovery rate of standard addition was determined. The results of the samples showed that except for the detected elements, the rest of the elements were not detected. The recoveries of the standard additions were all in the range of 99.6%-109.0%. The precision (RSD) was calculated by continuously measuring the measured value after adding the standard 7 times, and the RSD was less than 2.5%.

Table 5 Determination results of samples and recovery of standard addition (mg/Kg)

In this experiment, a super microwave rapid digestion diaphragm material was established, and the EXPEC 6000D ICP-OES was used to measure Al, Ca, Cd, Co, Cr, Cu, Fe, Hg, K, Mg, Mn, Na, Ni, Pb, Zn method of elemental content. From the experimental results, the linear correlation coefficients of the established standard curves are all greater than 0.9999, the recoveries of the determination standards are all in the range of 99.6%-109.0%, and the RSD<2.5%. Elemental quick analysis.

Appendix

Equipment and Consumables Solutions

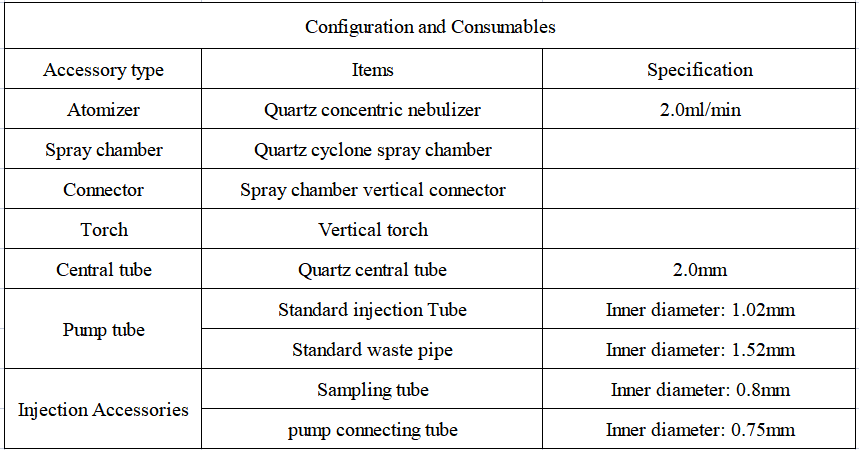

1. Configuration details of EXPEC 6500D standard sampling system

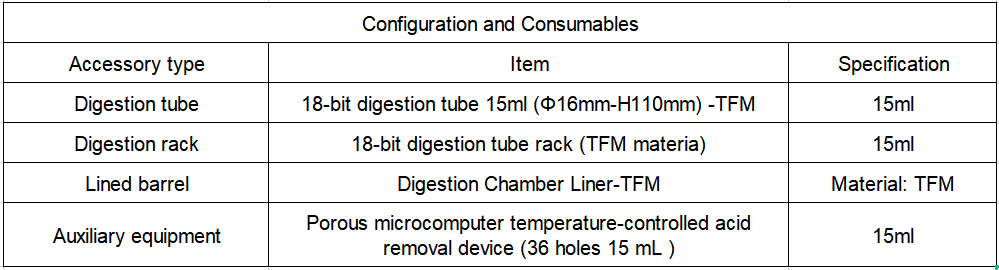

2. Configuration details of EXPEC 790S Super Microwave Chemical Workstation

3. Reagents and Standards