Smoking materials refer to various materials used in the process of manufacturing cigarettes or packaging cigarettes. It is an indispensable and important part of the production of cigarette products. It plays an important role in the process of developing new products, adjusting product structure, reducing tar and harm, and directly affects the quality and production cost of cigarette products. According to the provisions of the YC/T 316-2014 standard "Determination of Chromium, Nickel, Arsenic, Selenium, Cadmium, Mercury and Lead Residues in Tobacco Materials by Inductively Coupled Plasma Mass Spectrometry", smoking materials that need to detect heavy metal content include tobacco Base paper for tipping paper, tipping paper for cigarettes, inner liner paper for cigarettes, frame paper, cigarette paper, filter plug forming paper, cellulose diacetate tow for cigarettes, polypropylene fiber tow for cigarettes, triacetic acid for cigarettes Glycerides, water-based adhesives for cigarettes, hot-melt adhesives for cigarettes, etc. The traditional method of microwave digestion requires a minimum of 7 mL and a maximum of 10 mL of acid to digest such smoking materials, and too much acid will lead to the problem of high background . In addition, for tobacco water-based glue and tobacco triacetin, it is necessary to add a pre-digestion step. This is because the organic sample will release a large amount of gas during digestion, and the digestion tank cannot withstand the high internal pressure, which will lead to explosion.

Compared with the traditional microwave digestion instrument, the super microwave technology has a digestion temperature of 300°C and a pressure resistance of 20 Mpa. The core of its design is that the prepressurized digestion chamber (PDC) relies on the sealing effect of the entire chamber, rather than sealing each reaction tube individually. The internal and external pressure of each reaction tube is balanced , so there is no risk of tube burst. The application center uses super microwave technology to digest tobacco materials, reducing the amount of acid used for digestion, without pre-digestion, and the digestion solution is clear and transparent, which can meet the needs of back-end instrument testing.

Key words: super microwave, food, smoking materials, YC/T 316-2014

Experimental part

Instrument

Table 1 Super Microwave Digester

Reagents and Standards

Reagents: superior pure nitric acid, hydrochloric acid, hydrofluoric acid;

Pure water: 18.2 MΩ·cm deionized water (25°C);

Sample pretreatment

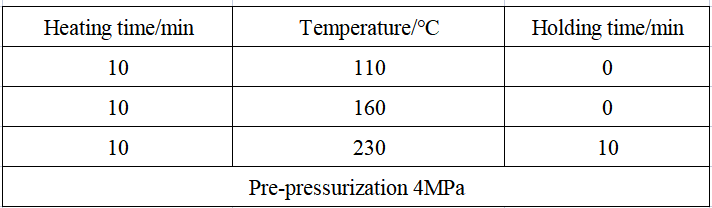

Weigh 0.2 g (accurate to 0.0001 g) of samples (cigarette paper, filter plug wrapping paper, tobacco water-based glue, tobacco flavor) into a digestion tube, add 3 mL of water and 3 mL of nitric acid, and transfer to a super microwave platform. Digest according to the program in Table 1, after cooling, dilute to volume with deionized water.

Weigh 0.2 g (accurate to 0.0001 g) of sample (cigarette tipping paper base paper, cigarette tipping paper, cigarette hot melt adhesive, cigarette lining paper, cigarette frame paper) into the digestion tube, add 3 mL Nitric acid, 1 mL hydrochloric acid, 1 mL hydrofluoric acid, transferred to a super microwave platform. Digest according to the program in Table 1, after cooling, dilute to volume with deionized water.

Weigh 0.2 g (accurate to 0.0001 g) of sample (cellulose diacetate tow for tobacco, polypropylene fiber tow for tobacco) into a digestion tube, add 3 mL of water, 3 mL of nitric acid, 1 mL of hydrofluoric acid, transfer to the super microwave platform. Digest according to the program in Table 2, after cooling, dilute to volume with deionized water.

Table 2 Super microwave digestion program

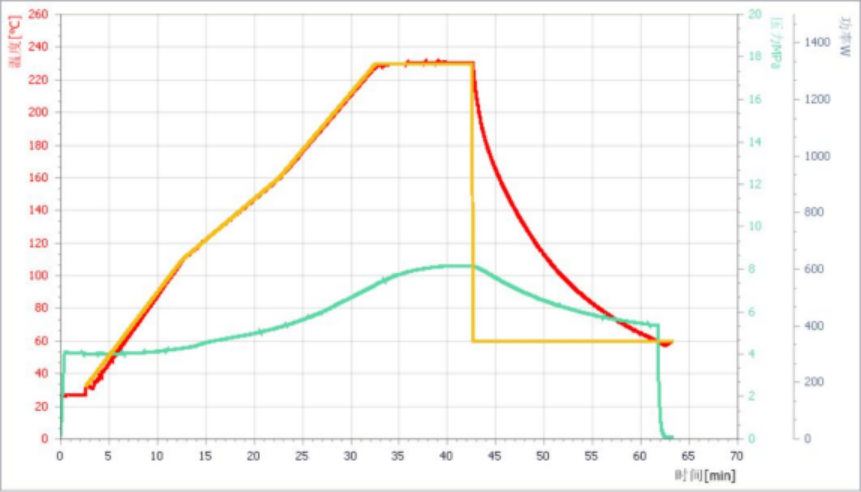

Figure 1 Super microwave heating curve

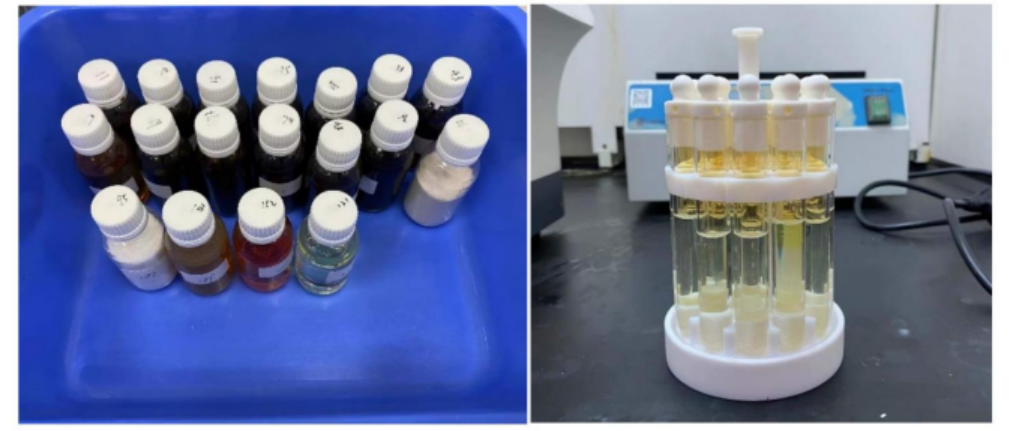

Figure 2 Pictures before and after sample digestion

Epilogue

This program uses super microwaves, which can digest smoking materials. The process does not require pre-digestion, the temperature is stable, the pressure does not change drastically, and the digestion solution is colorless and transparent. Due to the different types of tobacco materials, some samples will have white flocs or off-white precipitates after digestion, which will not affect the determination results of heavy metals after testing. If there are precipitates, they can be filtered or the supernatant can be injected.

Appendix

Equipment and Consumables Solutions

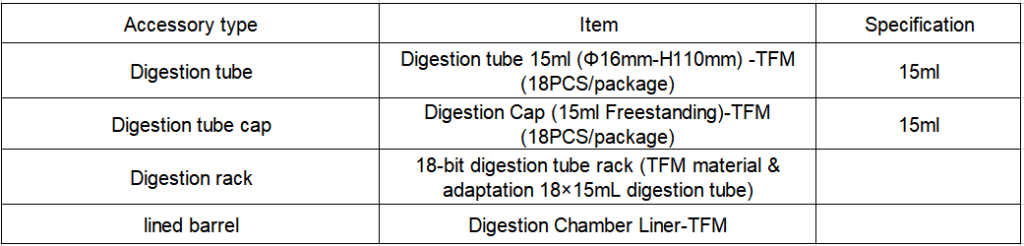

1. Super microwave configuration details

YC/T 316-2014