In recent years, the demand for lithium batteries for electronic products has steadily increased, and with the gradual expansion of the market size of new energy vehicles and the expansion of demand for energy storage batteries, the production scale of lithium batteries in my country has expanded year by year and has reached the world's leading level. Lithium-ion battery has the advantages of high voltage, high specific energy, long cycle life, environmental friendliness, good energy density and power density, etc. It is currently the power battery with the best comprehensive performance, and has been widely used in mobile phones, notebooks, rail transit, new energy vehicles and other fields.

A few days ago, a new energy vehicle caught fire in Shenzhen. The live video showed that the new energy vehicle was engulfed by the fire after the fire, and the whole vehicle was burned into an empty shell. Fortunately, there were no casualties. In fact, with the increase in sales of new energy vehicles, new energy vehicle fire incidents occur from time to time, and the cause of the fire is generally related to the battery. In order to reduce the occurrence of battery thermal runaway, the quality control of lithium battery raw materials is the top priority.

In the upstream and midstream of the lithium-ion battery industry chain, the quality control of raw materials and products requires the use of instrumental analysis methods to detect raw materials such as positive and negative electrode materials, electrolytes, and separators. According to the testing requirements, the application center has developed a microwave digestion lithium The application method of the battery material can realize the complete digestion of each component material of the lithium battery, reduce reagent consumption, reduce processing time, and improve pretreatment efficiency.

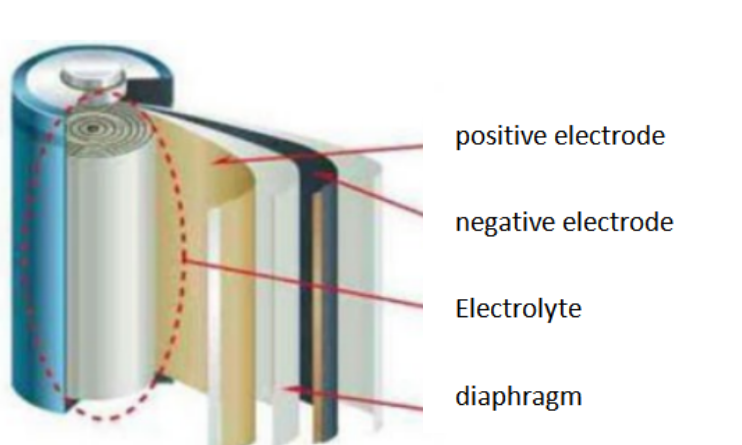

Composition of lithium battery:

| Composition | Material | Guideline |

| positive electrode | Lithium-containing transition metal oxides and sulfides are usually chosen.At present, lithium cobalt oxide, manganese acid, lithium iron phosphate and other lithium compounds are common cathode materials. | GB/T 23367.2-2009 Methods for chemical analysis of lithium cobaltate - Part 2: Lithium,Determination of nickel, manganese, magnesium, aluminum, iron, sodium, calcium and copper by inductively coupled plasma atomic emission spectrometry; GB/T 20252-2014 lithium cobalt oxide; GB/T 30835-2014 Carbon composite lithium iron phosphate cathode material for lithium ion batteries; |

| negative electrode | Lithium intercalation materials with low and stable lithium desorption and intercalation potentials. At present, the negative electrode active materials are mainly carbon materials and graphite, and metal oxides and alloy materials are also used as negative electrode materials. | GBT 24533-2019 Graphite anode materials for lithium-ion batteries; |

| electrolyte | At present, the lithium hexafluorophosphate carbonate system electrolyte is mostly used, and the gel state electrolyte is used for the polymer. | HGT 4067-2008 Lithium hexafluorophosphate and lithium hexafluorophosphate electrolyte Part 2:Lithium hexafluorophosphate electrolyte Electrolyte for SJ lithium-ion batteries (draft for comments) |

| diaphragm | Polyene microporous membrane is used. Such as PE, PP or composite membrane, especially the PP/PE/PP three-layer separator not only has a low melting point, but also has a high puncture strength, which acts as a thermal insurance. | DB44/T 1152-2013 Lithium-ion battery polyethylene separator |

Application of super microwave in digestion of various components of lithium battery

Experimental part

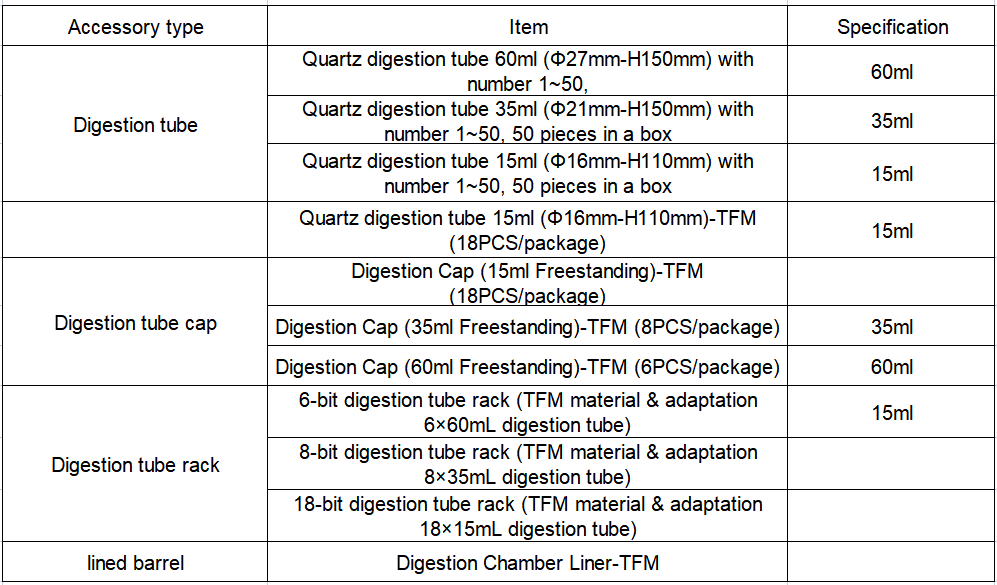

Table 1 Super Microwave Digester

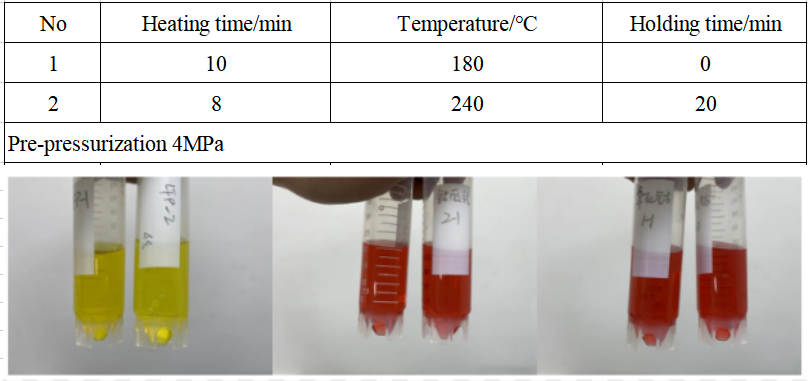

1. Lithium battery cathode material digestion scheme

Equipment: EXPEC Technology EXPEC 790S Super Microwave Chemical Workstation

Sample: lithium iron phosphate, lithium cobalt oxide, cobalt oxide

Reagents: premium pure nitric acid, hydrochloric acid, sulfuric acid

Digestion tube: 18 15 mL TFM digestion tubes

Digestion procedure:

Fig.2 Digestion results of lithium battery cathode material

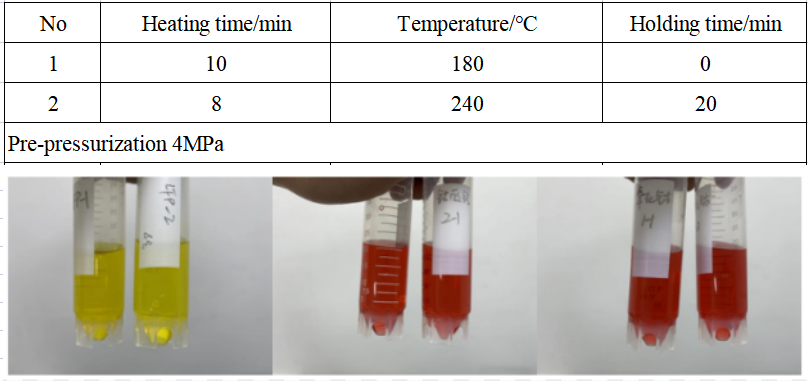

2. Lithium battery anode material digestion scheme

Equipment: EXPEC Technology EXPEC 790S Super Microwave Chemical Workstation

Sample: Graphite

Reagents: premium pure nitric acid, perchloric acid

Digestion tube: 18 15 mL quartz digestion tubes

Digestion procedure:

Fig.3 Digestion results of lithium battery anode materials

3. Lithium battery diaphragm material digestion scheme

Equipment: EXPEC Technology EXPEC 790S Super Microwave Chemical Workstation

Sample: polyvinylidene fluoride PVDF

Reagents: superior grade pure nitric acid, sulfuric acid

Digestion tube: 8-position 35 mL quartz digestion tube

Digestion procedure:

Figure 4 Digestion results of lithium battery separator materials

4. Lithium battery electrolyte digestion scheme

Equipment: EXPEC Technology EXPEC 790S Super Microwave Chemical Workstation

Sample: lithium hexafluorophosphate

Reagent: premium pure nitric acid

Digestion tube: 6-position 60 mL quartz digestion tube

Digestion procedure:

Figure 5 Lithium hexafluorophosphate digestion results

Epilogue

In summary, the microwave digestion method for lithium battery materials developed by this application center can digest a variety of different lithium battery materials at the same time, can meet the digestion requirements of samples, and can quickly, low-consumption, and fully digest lithium battery materials, significantly improving the former Processing efficiency and ease of operation.

Appendix

Equipment and Consumables Solution

1. Super microwave configuration details