Products

Customize user quality standards to determine whether the sample composition exceeds the standard and the results are clear at a glance.

Select suitable analysis program automatically , obtain accurate analysis results to achieve the best testing. Unknown samples can be analyzed easily.

Quickly identify the grades from the sample Analyzed results and monitor product quality.

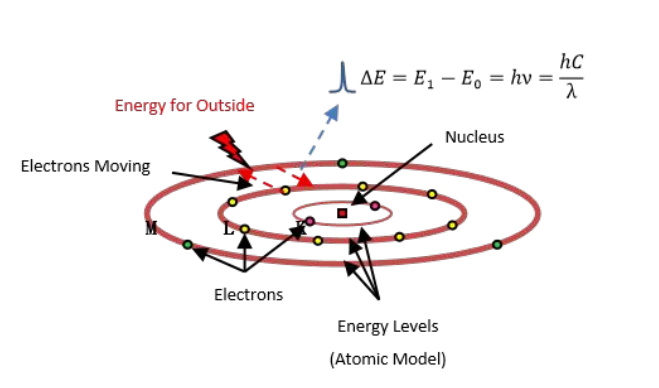

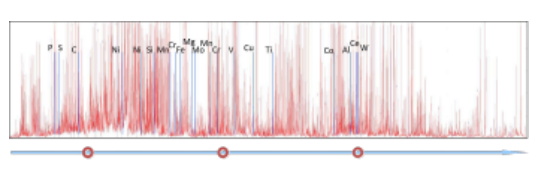

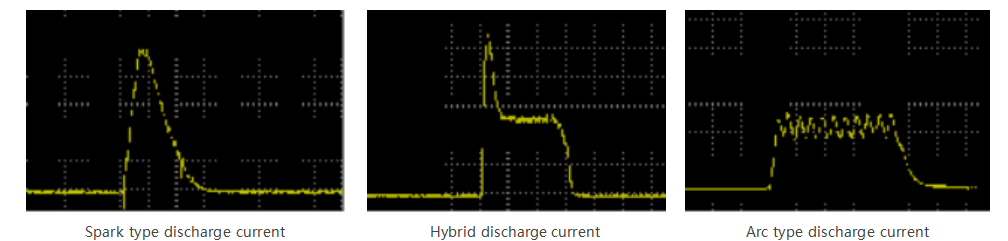

The spectrometer is a spectral analysis instrument using atomic emission spectroscopy technology , generally comprising Source , Spark Stand , Optic System , Detection System , Data Processing System , and other auxiliary systems such as Argon System , Power Supply System , etc. The basic principle is as follows. At the beginning of burning , argon will flush the spark stand into a pure argon environment. The electrode in the spark stand discharges with prepared metal samples to form a plasma. The light emitted by the plasma enters the optic chamber through the slit. After being divided by a grating , light of different wavelength is separated at different angles and irradiated on the detectors. The sensor converts the optical signal into an electrical signal , which is transmitted to the computer through the measurement system. The characteristic wavelength of the elements determine whether the metal sample contains the elements and the intensity of the spectrum determines the content. After computer processing , the analysis result is calculated , the content of each element in the metal sample is displayed on the computer monitor. The results can be summarized , saved , printed and transmitted.

The EXPEC 4820 and EXPEC 4850 metal analyzers are high-performance full spectrum spectrometers launched by Hangzhou EXPEC Technology. These series of products use scientific research grade CMOS as sensors and programmable full digital pulse source technology. They have many characteristics such as accurate analysis , stability , reliability and ease for use. They are suitable for the analysis of more than ten bases of metals such as Fe , Al , Cu , Zn , Ni , Co , Ti , Mg , Pb , Sn , and can be used in industries and fields including metallurgical casting , aeronautics and astronautics , precision manufacturing, intelligent vehicles , universities and colleges , etc.

The scientific research grade CMOS sensor has

lower noise and high UV response , which can

achieve the lower detection capability of PMT as well as the full spectrum analysis capability of CCD.

Scientific research grade photosensitive element , lower noise , strong anti - interference , stability u pg rade of a nti-halo technology

Detector has hig hintegration , which can avoid introducing noise into external circuits

Fast reading speed : OEO (Optimal Element Oriented) technology is a dopted , and pixe lsignals are read separately to achieve parameter optimization design.

Highe r UV res po nse sensitivity , no need for coating , achieving non - metallic element ( N , C , S , P ) a n a lys is , with better results.

Friendly software design , more concise and clearer interface , more convenient to use , and rich software functions meet the application needs of different customers.

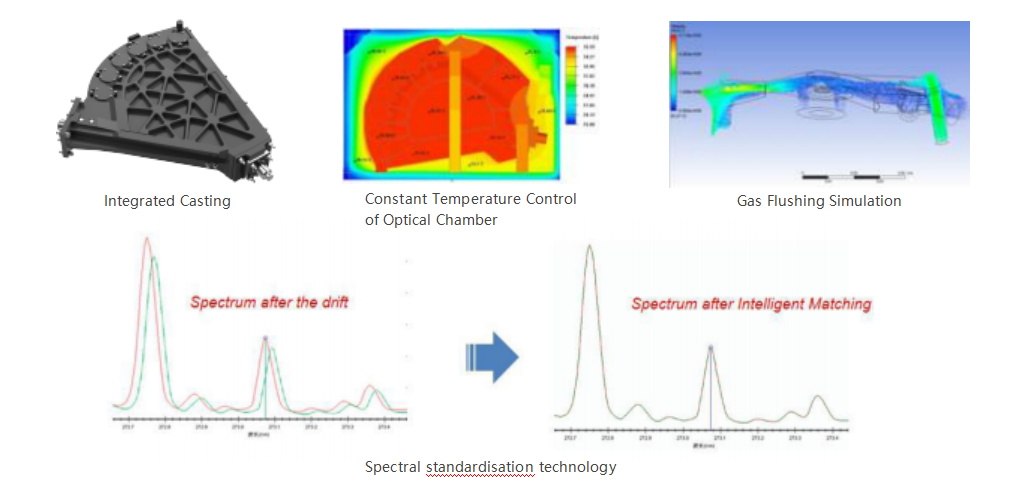

The perfect combination of high-quality hardware and specific algorithms provides multiple stability guarantees , better monitoring of instrument operation status, improving analysis results , and reducing standardization frequency.

Full spectrum detected makes it does not require additional hardware for adding bases and elements. The analysis range can be expanded through software , making it more flexible to use.

Intelligent program makes no need for model selected.

Customize user quality standards to determine whether the sample composition exceeds the standard and the results are clear at a glance.

Select suitable analysis program automatically , obtain accurate analysis results to achieve the best testing. Unknown samples can be analyzed easily.

Quickly identify the grades from the sample Analyzed results and monitor product quality.

Monitor the operation status of the instrument in real time and timely remind the maintenance and cleaning time of the instrument.

Free editing of carbon equivalent and corrosion resistance equivalent formulas control material properties.

EXPEC 4850 metals analyzer is a new high-performance full spectrum spectrometer developed by EXPEC Technology based on over 10 years of emission spectroscopy technology. This technology was first applied to the company's spectrometer M5000 . The instrument was released in 2009 and has passed more than 10 years of market testing and verification. Its stability and reliability have been tested by customers. The new EXPEC 4850 instrument uses a scientific research grade CMOS sensor as the detectors , follows the classic dual chambers Paschen -Runge type optical system design. Its excellent performance can meet the analysis needs of high-end users.

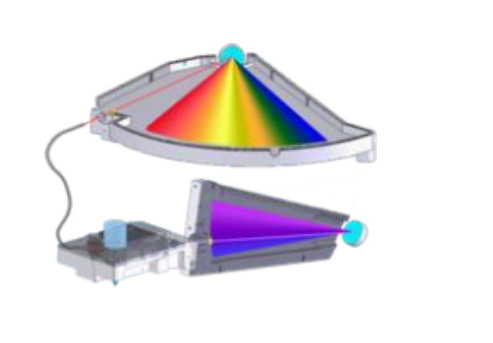

Advantages of dual-optics:

The dual-optics design can greatly improve the intensity of ultraviolet spectral lines and the measurement accuracy of ultraviolet elements without affecting the measurement of visible spectral lines. It also takes into account the advantages of high resolution and wide spectral wavelength range , with good performance for more elements.

An independently designed UV optical system that allows direct optical collection behind the spark stand , reducing optical intensity loss , improving the transmission efficiency of UV lines . It is specifically designed for measuring UV elements such as C , P , S , and N .etc , with higher grating lines for higher resolution.

The structure of the purer ultraviolet optical system with a small chamber (only 0 . 17L) is very simple and has no dead ends. Using an original argon purging technology , it can quickly flush air out to get higher argon purity and stronger ultraviolet optical detection capability , ensuring the analysis effect of ultraviolet elements.

| EXPEC 4820 | EXPEC 4850 | ||

| Optical System | Paschen-Runge optical system using multiple high-performance CMOS detectors | ||

| Optical chamber with argon self-purification system | Dual chamber argon purging optical system | ||

| Wavelength Range: 174~520 nm | Wavelength Range:140~680nm | ||

| Source | Programmable full digital pulse source | ||

| High energy pre-ignition technology, ignition pulse: 1~14Kv | |||

| Maximum discharge frequency: 1000Hz, Maximum discharge current: 400A | |||

| Spark excitation pulse: 20~230V, Arc excitation pulse: 20~60 V | |||

| Power supply and environmental requirements | Power supply voltage: (220 ± 20) V AC, (50 ± 1) Hz, single power supply with protective grounding | ||

| Maximum excitation frequency: 400W, Average standby power: 50W | |||

| Working temperature: 10~30 ℃, Storage temperature: 0~45 ℃, Working humidity: 20~80% RH | |||

| Spark Stand | Opened sample operation platform, which can be equipped with various sample adapters for special applications to meet different small sample analysis needs | ||

| Optimized argon flushing design, better argon saving and spark stability. | |||

| Easy to clean and maintain, intelligent reminder of maintenance cycle. | |||

| Argon | Aperture of spark stand: 13mm (optional: 6mm) | ||

| Purity: 99.999%, Pressure: 0.5MPa | |||

| Burning flow is about 3.5L/min, maintaining and standby flow is about 0.1L/min | Burning flow is about 3.5L/min, maintaining and standby flow is about 0.2L/min | ||

| Dimensions and weight | Length: 818mm, width: 590, height: 396mm weight: about 70Kg | Length: 623mm, width: 735mm, height: 443mm weight: about 70Kg | |

| EMC | IEC 610004-2, 61000-4-4, 61000-4-5 | ||

| Model | F | None | Dual optical chamber configuration, best UV analysis capability, capable of accurately analyzing N elements, meeting high-end analysis requirements for various matrixes such as Fe, Al, Cu, Zn, Ni, Ti, Mg, Co, etc. |

| N | Suitable for all matrix analysis and can meet the matrix analysis requirements such as Fe, Al, Cu, Ni, and Zn | Dual optical chamber configuration, strong UV analysis capability, meeting various matrix analysis requirements for Fe, Al, Cu, Zn, Ni, Ti, Mg, Co, etc. | |

| S | Suitable for nonferrous metal analysis and meet the matrix analysis requirements such as Al, Cu, Zn, and Mg | Single optical chamber configuration to meet Cu, Zn, and Mg etc. | |

Leave your needs, we will get in touch with you as soon as possible!