Products

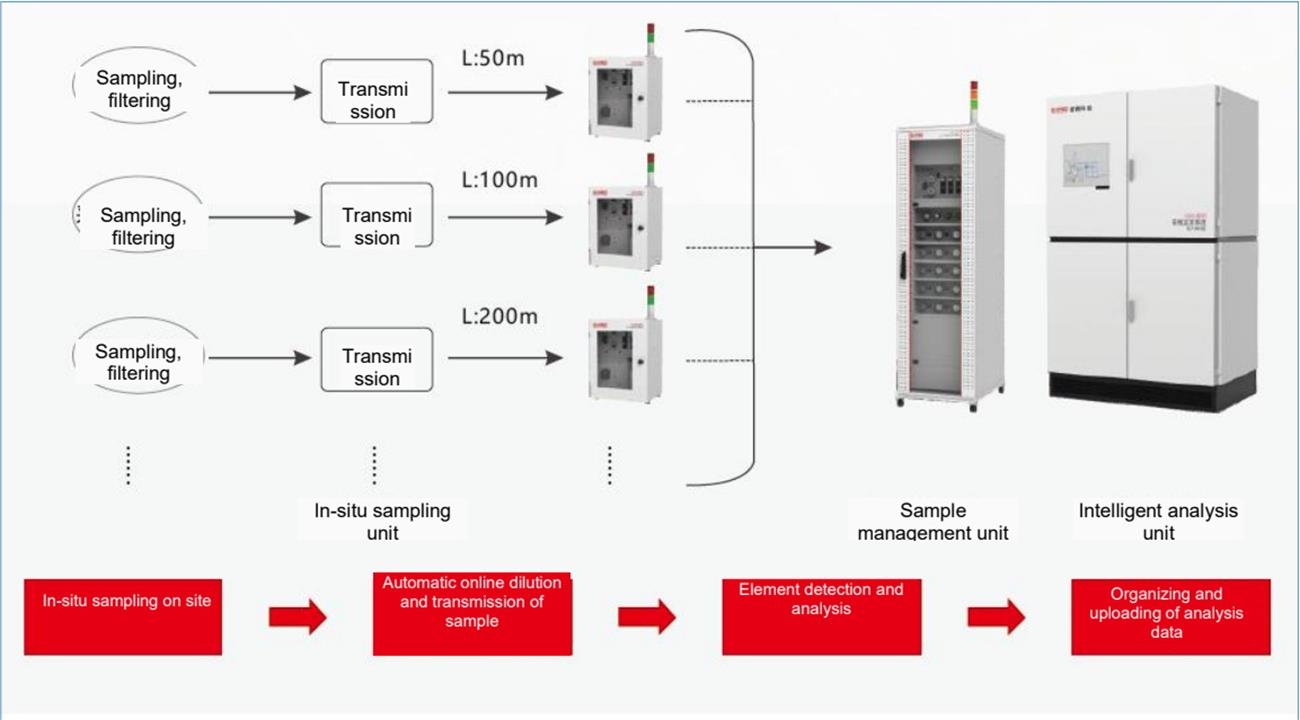

1 analysis unit could support 1- 15 sampling units.

≤ 300 meters

≤ 20 minutes

RS232/485 and RJ45 interfaces, supporting the standard protocol communication of the interfaces.

Intelligent manufacturing is an important measure to implement China's strategy of becoming a strong manufacturing country. Accelerating the promotion of intelligent manufacturing is an important focus for accelerating the deep integration of industrialization and informatization in China, and promoting the supply-side structural reform of the manufacturing industry. It is of great significance for reshaping China's new competitive advantages in the manufacturing industry. In the Guidelines for the Construction of National Intelligent Manufacturing Standard System, it is stated that the focus of intelligent equipment standard construction includes the standards for the perception, collection, transmission, processing and feedback of technical process information. Therefore, an online monitoring system that can achieve automatic, real-time and continuous monitoring has become a key development direction of "intelligent perception" in intelligent factories.

In the actual process of industrial production, timely acquisition of material component data during the production process is crucial for product quality control. Traditional manual sampling and chemical analysis can no longer meet the needs of enterprises for automatic batching in the production process. Therefore, timely obtaining the component concentration data of production material is of great significance for stable production control.

At present, the production enterprises mainly adopt the on-site manual sampling or conventional instrument methods to monitor the relevant data. Due to the need for monitoring a large amount of data,the poor production site environment, and the high labor input, there are a series of problems such as poor real-timeness of data, poor sample representativeness, and large labor impact, which cannot fully meet the stable control requirements of the production process.

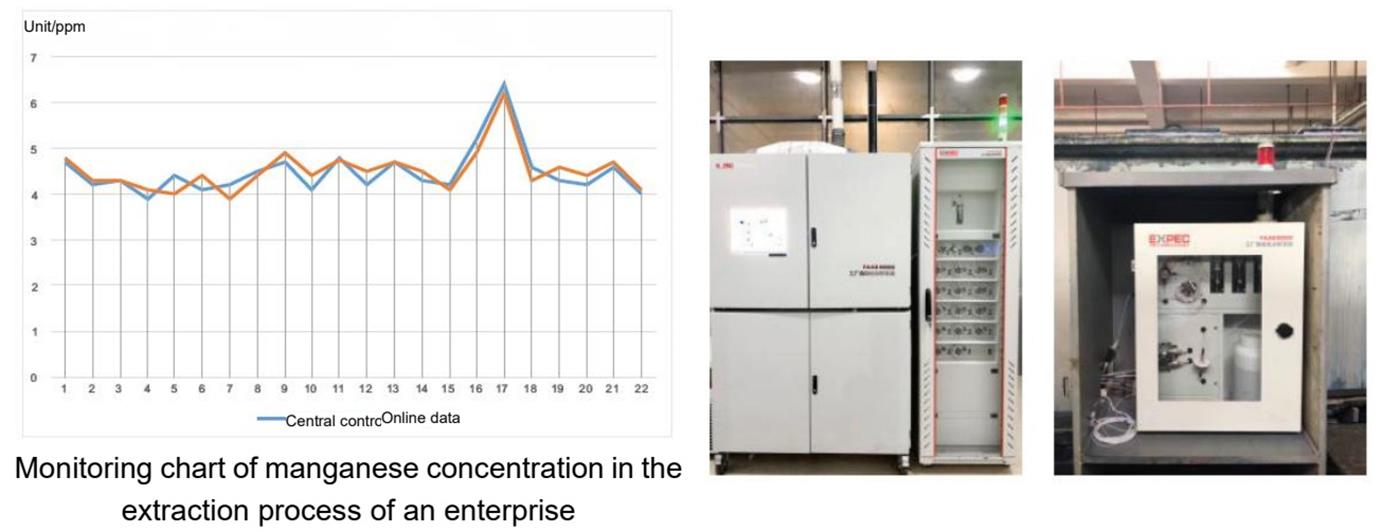

In response to the current issue of manual monitoring in enterprise production, EXPEC Technology has launched the FAAS 8000 factory automation analysis system, which could achieve the real-time, continuous and online monitoring at multiple points during the process, as well as timely and accurately obtain the element concentration information at each process point. Thus, the investment in daily manual monitoring can be greatly reduced, and the automatic optimization control of production processes can be achieved through online data monitoring, further improving the automation, intelligence and informatization of the production process, thereby enhancing the stability of the production process.

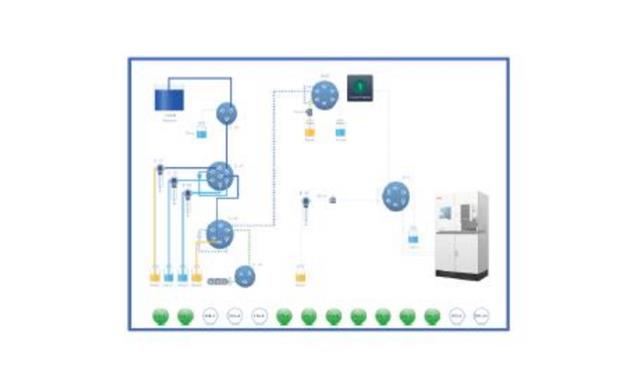

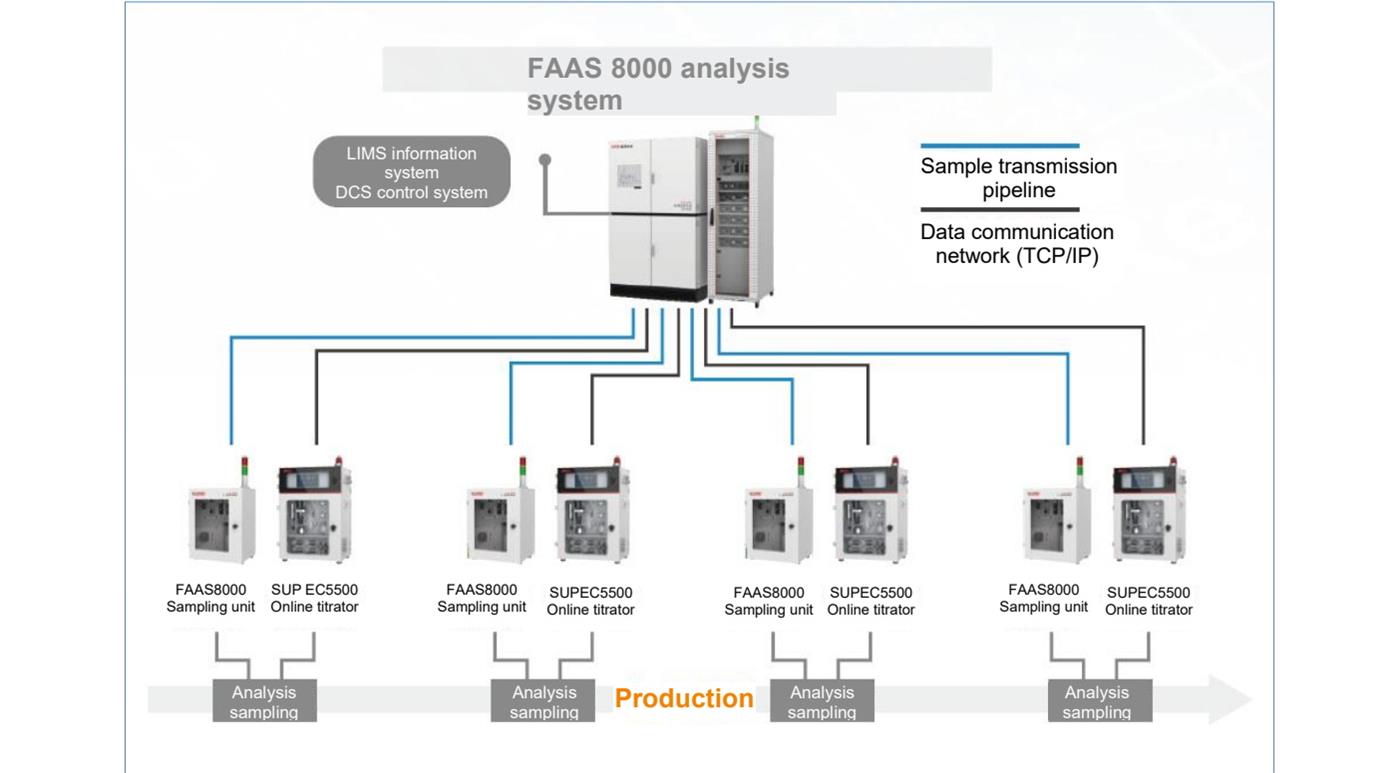

The FAAS 8000 factory automation analysis system is based on the laboratory analysis instruments and uses the system architecture of "distributed in-situ sampling + central analysis server", thus achieving the rapid online monitoring of multiple elements of liquid samples in industrial production process. Thereby, the key technologies of flow path, such as remote pneumatic sample delivery, second-level non destructive transmission and high-precision online ten-thousand-fold dilution, were developed to achieve the real-time and rapid online monitoring of multi-element with long distance at multiple points, providing effective support for the production process optimization, product quality improvement, energy conservation and cost reduction of the enterprises.

FAAS8000 supports the inductively coupled plasma optical emission spectroscopy (icp-oes), inductively

coupled plasma mass spectrometry (icp-ms) and atomic fluorescence spectrometry (afs) to meet the

analysis requirements of samples with different concentrations and characteristics.

ICP-OES (Inductively Coupled Plasma Optical Emission Spectroscopy): To determine the concentration

of 72 metal elements and some non-metallic elements from ppm to ppb level.

ICP-MS (Inductively Coupled Plasma Mass Spectrometry): To determine the concentration of 75 metal elements and some non-metallic elements from ppb to ppt level. AFS (Atomic Fluorescence Spectroscopy): To determine the trace elements such as arsenic, antimony, bismuth, mercury, selenium, tellurium, germanium, etc.

The FAAS8000 factory automation analysis system can be integrated with the SUPEC5500 online titrator of EXPEC Technology to achieve the analysis of various factors in liquid samples from trace to macro-concentration during the factory production process.

The FAAS8000 system supports multiple communication protocols such as TCP/IP and MODBUS. Analysis of concentration data can be seamlessly transmitted and interacted with system data of the existing laboratory information management systems (LIMS) and the distributed control systems (DCS) through heterogeneous communication

The FAAS 8000 system is applicable to the hydrometallurgy of non-ferrous metal, new energy battery,

fine chemicals and pesticide production, and it can be extended to the special industries such as

high-purity reagents to achieve the online analysis of liquid sample elements during the production.

Environmental monitoring

Food safety

Biomedicine

Forensic and Toxicology

Biomedicine

Other application scenarios involving non-methane total hydrocarbon monitoring

System performance

|

Performance |

Indicators |

|

Analytical methods |

ICP-OES (ppb-level detection limit), ICP-MS (ppt-level detection limit), AFS (ppb-level analysis of arsenic, antimony, bismuth, etc.), and the titration method (macro-analysis) |

|

Sampling capability |

1 analysis unit could support 1- 15 sampling units. |

|

Sample transmission distance |

≤ 300 meters |

|

System analysis time |

≤ 20 minutes |

|

Communication interface |

RS232/485 and RJ45 interfaces, supporting the standard protocol communication of the interfaces. |

Application value

|

Before use |

After use |

|

|

Manual sampling frequency |

12-24 times/day |

2-3 times/day |

|

Data detection interval |

2-4 hours |

15-30 minutes |

|

Production material loss |

Unchanged |

Reduced by 20% |

|

Labor intensity of laboratory test |

High |

Supervision and verification |

Leave your needs, we will get in touch with you as soon as possible!