Products

EXPEC1950 open-path infrared gas analyzer can perform remote, non-contact, intelligent continuous monitoring of multiple non-point source toxic and harmful gases based on the open-path FTIR remote detection, outputting qualitative and quantitative analysis results in a real time manner.

The instrument is divided into emitting side and receiving side. The emitting side emits an expanded collimated infrared beam, which is received by the receiving side after passing through the detected area, to perform qualitative and quantitative analysis of gases based on the infrared fingerprint spectra of the gases using the deep neural network

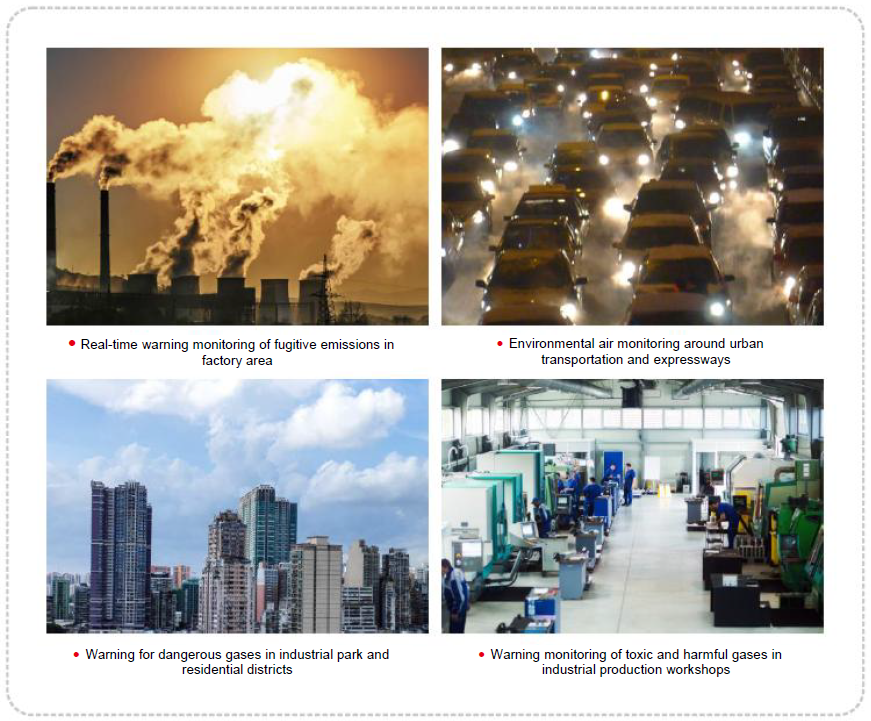

algorithm. The instrument is widely used for monitoring of leakage, and diffusion, etc. of toxic and harmful gases in such fields as chemical industry, environmental protection, transportation, and industrial manufacturing.

The instrument has an opposite-type split design, without reflector mirror array. It has a flip-back-type body frame, allowing simple and convenient maintenance. The detector is limited by multiple points, ensuring the measurement accuracy after repeated mounting and demounting.

The instrument body is protected in a hermetic manner, and adapts to different pollution environments. Multiple detectors, telescope, and other accessories are provided to adapt to different monitoring demands. The instrument can be used

alone, and multiple ones can be networked in a segmented manner, to form an optical fencing.

The instrument can realize simultaneous alarm for multiple mixed gases through identification of fingerprint spectra. The system can intelligently determine the measurement scheme and automatically perform background correction.

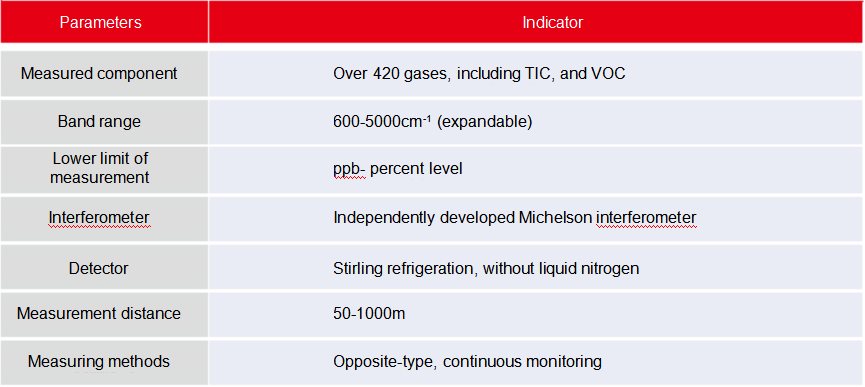

There are multiple environmental monitoring models and expert spectrogram database built in the system, so the system can monitor >420 routine gases, toxic industrial compounds (TIC), and volatile organic compounds (VOC), etc. The system supports online upgrading of monitoring models andspectrogram

database.

The instrument uses MCT detectors based on Stirling deep refrigeration, achieving ppb-percent level monitoring based on the deep neural network analysis algorithm.

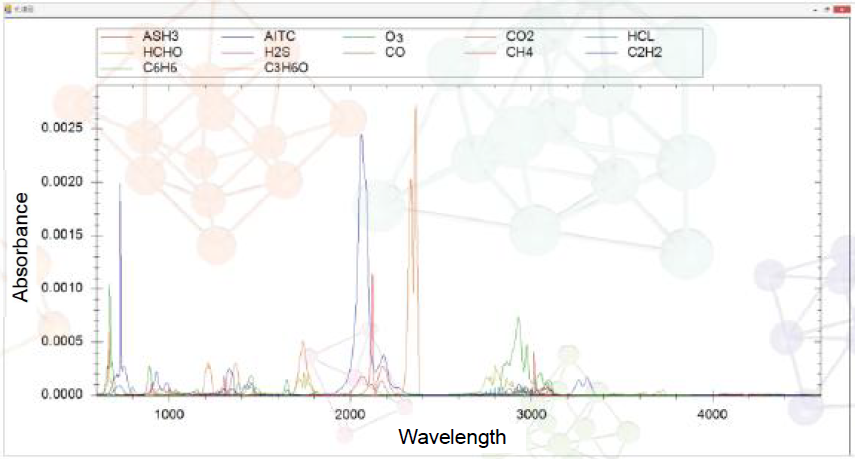

Expert database

A spectrogram database containing over 560 toxic and harmful gases, including VOC and TIC; multiple

application analysis models, supporting customization of analysis model.

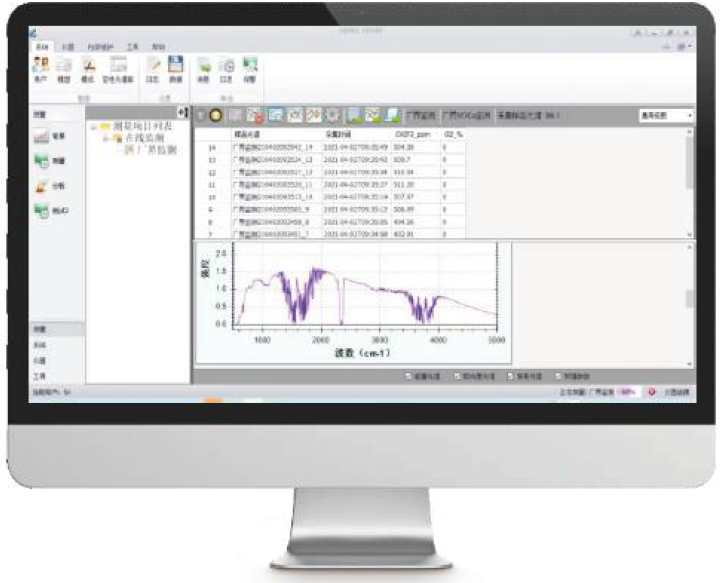

Intelligent monitoring

The system intelligently determines a measurement scheme, automatically selects a background

calibration mode, to obtain gas components and contents and create spectrogram and report table by

comparing with the expert spectrogram database using multiple patented algorithms. The analysis time is

less than 1s.

Intelligent warning

When detecting that the gas concentration reaches a dangerous value, the instrument triggers an alarm,

giving light and sound warning and reporting to the control center. The alarm levels can be set to multiple levels through self definition.

Data storage

The monitoring data is displayed locally and in the control center in a real time manner, saved locally and

uploaded to the server, which can be invoked and analyzed at any time. The measurement results

automatically form daily, monthly and yearly monitoring reports.

An EXPEC1950 open-path infrared gas analyzer is installed at the riverside of the factory boundary in a chemical industrial park, used for all-weather fully-automatic monitoring toxic and harmful gases diffused to the surrounding areas from the park. The equipment is installed in the safety station room, mainly monitoring such gases as hydrogen sulfide, ozone, nitrogen dioxide, sulfur dioxide, and carbon monoxide. The equipment automatically creates specific monitoring models according to the monitoring environment.

Safety guarantee in industrial park

Leakage monitoring of stored gas

VOC emission testing of combustion unit exhaust gas

Leakage accident in storage of dangerous chemicals

Leakage accident in transportation of dangerous chemicals

Petrochemical industry

Leave your needs, we will get in touch with you as soon as possible!