Products

Potentiometric titration

Photometric titration

Direct potential

Colorimetric method

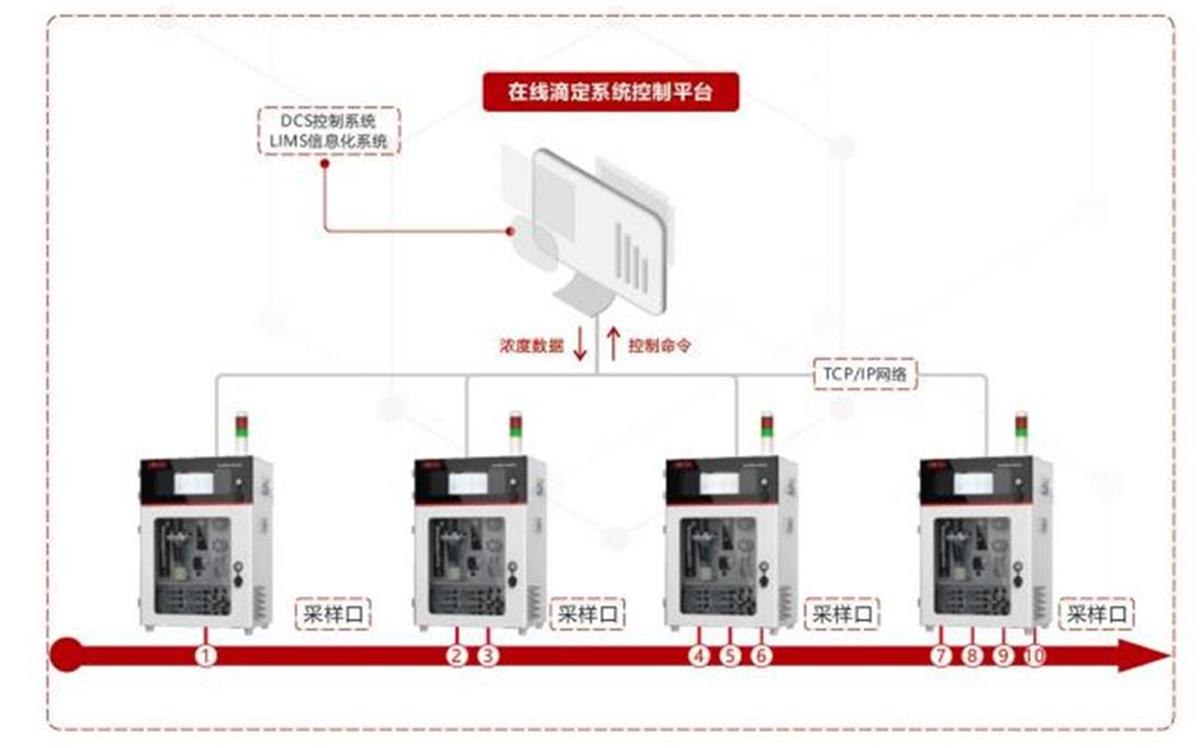

SUPEC 5500 online titration analysis system of EXPEC Technology, including the three specifications of single-factor photometric titration, single-factor potentiometric titration and double-factor titration, has the functions of automatic sampling, automatic filtering, automatic dilution, automatic titration analysis, automatic cleaning and waste discharge, capable of realizing pH, ORP and complexometric titration. Besides, the system can continuously obtain the key parameter information in various industrial manufacturing processes for 7 days * 24 hours, thus suitable for the substance concentration analysis in various industries such as petrochemical, chemical, metallurgical, industrial water, food, semiconductor, pharmaceutical, papermaking, etc.

The online titration analysis system can collect samples online during the production process, with a single system supporting 1-4 sampling points within 20m. Depending on the field working conditions, the single or multiple systems can be selected to achieve the full coverage of industrial field testing sites. Besides, the DCS/LIMS system can be connected to achieve the efficient and convenient intelligent management.

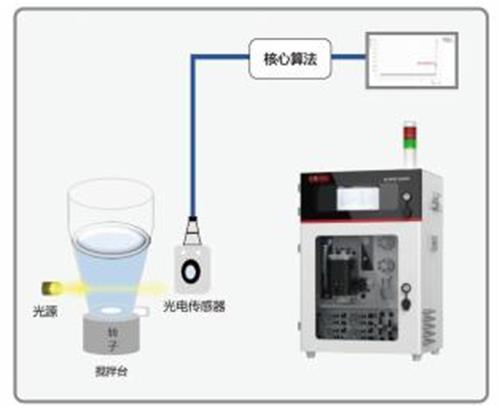

Photometric titration is based on the selective absorption of light by substances (Lambert-Beer law), using a contactless photometric sensor with wavelength adjustable to achieve the concentration determination of different substances.

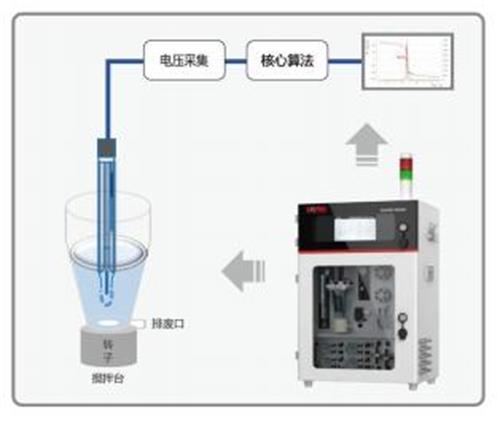

Potentiometric titration is based on the selective response of electrode-collected voltage to concentration (Nernst equation), and adopts the different types of electrodes to determine the concentration of different substances.

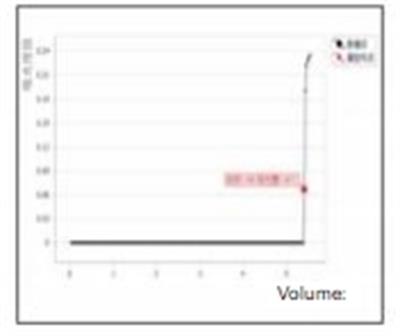

The determined ion concentration undergoes a sudden change near the stoichiometric point, and the results are accurate and reliable without the need for calibration.

The point at which the color changes initially, i.e. the inflection point of the titration curve, can be used to titrate the test solution with a color change at the end point.

It is to find the concentration on the

standard curve according to the potential

value of the component solution to be tested.

Thus, this method has a fast analysis speed and

a wide measurement range.

It is to find the concentration from the standard curve according to the absorbance of the component solution to be determined, which is simple, rapid and suitable for the analysis of a large number of samples.

The four detection methods should be determined based on actual detection requirements, and the following table is not exhaustive.

|

Compositions |

Potentiometric titration |

Photometric titration |

Direct potential |

Colorimetry |

|

Acidity |

• |

• |

|

|

|

Alkalinity |

• |

• |

|

|

|

Ammonia |

|

• |

• |

|

|

Chlorine |

• |

|

• |

|

|

Zinc |

|

|

|

• |

|

Copper |

|

|

• |

• |

|

Molybdenum |

|

|

|

• |

|

Iron |

|

|

|

• |

|

Vanadium |

|

• |

• |

|

|

Manganese |

• |

• |

|

|

|

Total rare earth |

• |

• |

|

|

|

Fluoride |

|

|

• |

• |

|

Hydrofluoric acid |

|

• |

|

|

|

Hardness (calcium magnesium) |

|

• |

|

|

|

Phosphate |

|

|

|

• |

More convenient: The on-site operation of touch screen terminals, and the remote control and upgrade of central control platform software

More functions: Online monitoring, method configuration, permission grading, data query, and status indication

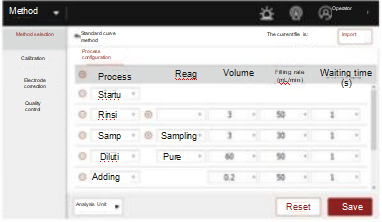

More flexible: Open interaction, so that the users can customize and edit the parameters as required.

More reliable: Data backup, data traceability, and audit tracking

More user-friendly: Graphical interaction, with multilingual version and user-friendly interface design, so that it is easy to operate.

Capable of monitoring the system operation status, sample concentration, liquid level of various reagents, instrument temperature and pressure, and issuing the alarm messages in time.

It is flexible to set and save the titration parameters, analysis methods, calculation formulas, cleaning times, calibration frequency, dynamic equivalence point titration, monotonic equivalence point titration, etc.

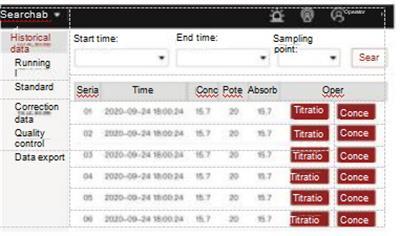

The historical data, operation logs, alarm information, calibration information, quality control records, etc. can be queried and exported.

Leave your needs, we will get in touch with you as soon as possible!